TECH5 is a regular feature where EngineLabs asks industry leaders five technical questions. This week’s guest is Ron Rotunno, performance product manager at Fel-Pro, which is a division of Federal Mogul.

TECH5 is a regular feature where EngineLabs asks industry leaders five technical questions. This week’s guest is Ron Rotunno, performance product manager at Fel-Pro, which is a division of Federal Mogul.

EngineLabs: What are the unique challenges in sealing high-performance engines?

Rotunno: Sealing high-performance engines poses challenges not normally encountered when sealing their stock replacement brethren. As such, these engines require specific sealing technologies and a more in depth understanding of each platforms intended use. I break down these challenges by what I call environmental issues….those that are a direct result of making sustainable horsepower; things like high combustion pressure, casting motion (and associated cylinder head lift), temperature, the presence of crankcase pressure and engine rpm. Just like the weather, there’s not a lot you can do about these things other than prepare for them. On the other hand, there are what I call self-induced factors. These are the factors that come once the engine is put into service. They include things like tune up, fuel quality, maintenance and all of those things that come up on the track (think hot dog wrapper on the grill opening of a stock car). Also included are the wide variety of assembly procedures employed by race engine builders.

EngineLabs: What is casting motion?

Rotunno: When an engine creates power, it wants to push the heads right off the deck of the engine block. We call this head lift, and this is one of the most challenging aspects of sealing, especially when power adders are used. As a general rule, the more pressure, the more head lift. That said, some head/block combinations have the potential for more head lift given relatively low combustion pressures. This is due generally to the design integrity of the castings, the number and layout of head bolts and torque limitations. The key is to know what you’re dealing with before designing a head gasket to seal these platforms. Know where the head lift occurs, how much of it occurs and at what power levels. Partnering with casting manufacturers helps but there is no replacement for working directly with race engine builders. You learn something new with each conversation, prototype part and hands on visit. We also invest a lot of time and money doing our own in house investigative and validation work. Through a variety of tests we are able to simulate conditions that most engines (race or not) will ever have to endure. Thermal shock tests are a great example…..think of an engine going from operating temperature at wide open throttle, being chilled to the point where frost forms on the castings and then back to WOT inside of 10 minutes. There are also others tests we employ to look specifically at head lift.

EngineLabs: You mentioned thermal shock. How does temperature affect sealing?

Rotunno: Combined with head lift, temperature accounts for most of the issues faced when sealing a high performance engine. Localized “hot spots” can cause castings to expand, crushing head gasket material to the point where it loses its ability to recover. Recovery refers to a head gasket’s ability to rebound and maintain contact sealing stress between head and block castings. Some areas are just more high heat. Think small-block Chevy with back-to-back exhaust valves, and that can be planned or designed for. It’s when there is some sort of anomaly in the engine, like bad or insufficient water pump, poor radiator, air pockets etc. That really puts the sealing components to the test. Add in, detonation, pre-ignition, poor fuel, low coolant, no coolant or an overzealous crew chief (more grille tape is better) and things get even more challenging. Our jump-off point is understanding the engine platform, its faults or weaknesses, its intended use and its expected duty cycle (think of stock car versus drag car or street car). Once we determine these things we can select a material combination and combustion seal design that will provide the best, most consistent seal. Regardless of material selected, any head gasket must seal combustion, fluids (oil and coolant) and allow for casting motion.

EngineLabs: What’s leading-edge technology in head gaskets?

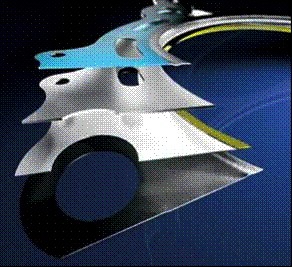

Rotunno: Multi-Layer Steel (MLS) cylinder head gaskets have become an increasingly significant part of our high-performance sealing strategy over the last decade. Fel-Pro PermatorqueMLS Performance head gaskets feature four layers of stainless steel with a thin rubber coating that will enable the gasket to seal surface finishes up to a 60 Ra (roughness average). At the heart of the Fel-Pro design are three embossed (active) layers that combine to seal the combustion opening and other critical sealing areas of the gasket. The fourth layer used is what’s called a shim layer. The shim layer allows us to dial in the desired overall gasket thickness and also provides the platform for our laser welded stopper layer. The laser-welded stopper layer appears as a thin steel ring on the shim layer of the finished part, this “stopper” provides a positive stop for the emboss bead to prevent overcompressing the bead during engine operation (racing), it also enhances the integrity of the combustion seal and can reduce head lift.

EngineLabs: What are the most common mistakes in installing head gaskets?

EngineLabs: What are the most common mistakes in installing head gaskets?

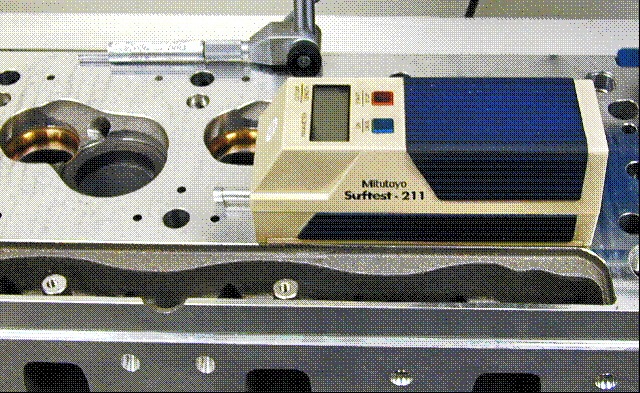

Rotunno: When installing MLS head gaskets, it’s all about surface prep. Make sure the casting surfaces are within that 60 Ra or smoother value (ra is an inverse scale so a 30 Ra for example is smoother than a 60 Ra surface finish) and that the surfaces are flat. End to end no more than .002-inch or .003-inch out of flat. Make sure the head bolts are in good condition. Threads should be true and free from defects. Chase the bolt holes in the block and use a high quality lubricant both on the threads and the underside of the bolt heads. Torque in sequence in three equally spaced increments. If time allows, let the assembly sit overnight and crack them loose in the morning (one at a time) and draw them back up to help condition the threads. Finally, have your torque wrenches calibrated.