Centrifugal supercharging has quickly become one of the racer’s go-to methods of boosting engine power; its relative user-friendliness combined with potentially immense power gains have pushed it towards the front of the list when it comes to building a successful racing program.

A few years ago, engine builder and tuner extraordinaire Steve Morris of Steve Morris Engines had an epiphany—he felt that there were improvements to be made by tweaking the internals of ProCharger‘s range of race blowers, and subsequently got to work on figuring out the details. Hundreds of hours of research and development later, he demonstrated the modifications through dyno testing, and now offers those modifications to the public.

There was plenty of testing prior to releasing the finished ProVolute bell design – including several readily-available pieces from other sources.

ProVolute Internal Mods

The ProVolute CNC-machined internal modifications center around ProCharger’s superchargers; most importantly, the last-generation F-Series superchargers, like the F-3R 139mm “big boy” blower and the F-2, which have what Steve describes as “older technology” inside.

One thing Morris stresses right off the bat is that the ProVolute modifications do not include tightening up the supercharger’s internal dimensions.

Shown are just a small grouping of engineering revisions for the ProVolute internal machining process.

“People have a misconception that if you just tighten up the clearances on the superchargers they get better; that is not what we do. As a matter of fact, most of these blowers, after we perform the modifications, we actually add more clearance from the impeller to the housing,” says Morris.

One of the main reasons for adding this additional clearance is to prevent the impeller from crashing into the housing, promoting longevity as the horsepower levels rise with the modifications performed.

“Internally, we change the shape of the diffuser plate. This also resets the height of the impeller within the housing by pushing the impeller further into the housing. This is only because we’re changing the shape of the diffuser plate,” he explains.

Various modifications were tried and tested to arrive at the optimal shape and profile of the landing area on the diffuser plate.

The diffuser plate is located between the impeller and the supercharger’s volute (compressor housing) and is designed to take the kinetic energy (high velocity) of the incoming air path and convert that velocity into pressure by gradually slowing (diffusing) the air before sending it into the volute. Each SME-modified diffuser plate is fitted to the individual compressor housing, so SME must have the supercharger on-hand—you can’t just order the plate separately.

Improving the diffuser plate sounds simple, but it wasn’t—that’s where the hours and hours of development time came into the picture.

The ProVolute Internal Mods On ProCharger’s D-1SC

“Basically, there’s a hump in the diffuser plate. We’ve figured out where the position of the hump needs to be, how high it needs to be, and what the squish area needs to be between the housing and the backing plate,” says Morris.

“I’m not an engineer, I didn’t figure this out with CFD, or anything like that. We test stuff. Put it on the dyno, make a change, go back to the dyno again. We probably went through four blowers and covers for the first F-2 we developed. We even used Bondo on the entire surface, cutting it low, using body filler and machining it the way I wanted to get temporary testing data. Once we figured out what we needed we could finalize the design.”

By looking at other products in the marketplace, including turbochargers, and investigating the differences between the varying styles, the grunt work began with different designs of the diffuser plate to try to improve the supercharger’s performance. The entire point of this research was to do one thing – help the air to exit off the exducer tip in a clean manner.

“Sometimes the superchargers have a large variance [from the manufacturing process], and we started looking at this in the context of exducer tip clearance to the housing. Once we looked at that, we found that one blower might have .075-inch clearance, and yet another might have an eighth-inch (.125-inch) of clearance,” says Morris.

Sometimes there is not enough material to properly perform the complete machining. A ring is welded internally and the correct profile can then be achieved (left to right).

As you may recall from some of our EngineLabs articles in the past (seen here), Morris flogs his dyno regularly with all types of supercharged engine combinations, and he has proven the performance of the design on older ProCharger superchargers from the “baby” D-1 through the F-1R and F-2 all the way up to the F-3R.

Newer designs like the F-1X, F-1X-12, and F-3R 136 don’t get the same level of modifications, as ProCharger improved upon their internal design—similarly to the SME modifications—before ever releasing that lineup of superchargers.

“We started this whole thing by playing with the internal clearances, but the problem we found is that you couldn’t tighten up that clearance due to the shape of the diffuser plate, and that’s when I started thinking about changing the shape of the plate to get the clearance where we’d want it at the exducer tip,” says Morris.

ProVolute Before/After ProCharger F-1R Testing

As we can see from these testing results (from the F-1R video above), the ProVolute internal and external mods combine for a gain of 132.6 horsepower and 87.8 pound feet of torque on the test engine.

As the ProVolute internal modifications are proprietary to SME, Morris didn’t want to give away too many secrets in terms of the actual design, but one thing is proven—on the dyno, Morris claims gains of up to 100 horsepower or more are possible from the pair of ProVolute modifications (including the inlet bell, discussed below).

“It’s like the difference between a really good air gun versus an open hose. Clean, non-turbulent air versus air that just goes out and is very inefficient,” says Morris. “Since the air is less turbulent as it comes off the exducer tip, you’ll also see slightly cooler outlet air temperatures.”

At one point Morris even tried a complete three-piece billet volute for the F-3R supercharger and tested it. “We were 100 horsepower better on the F-3R 139mm; at peak RPM and peak horsepower we were down a little bit, but it was better on the bottom end,” he says.

Right around the same time, ProCharger debuted their 136mm F-3R revised design, and Morris pulled the plug on the design as he didn’t feel there was enough of a market at that point in time to make it financially feasible to produce in small volume.

The price point on the internal modifications runs a customer $850—which comes out to $8.50 per horsepower on the conservative side, quite possibly the most cost-effective upgrade for a racer looking to pick up a chunk of horsepower without having to lay out the cash for an all-new supercharger.

Seen here on the right is the billet volute design SME tested. It worked to build power down low, but was ultimately deemed unsuitable for production.

The ProVolute Inlet Bell

When Is The Inlet Bell Effective?

Certain race classes require the use of factory-style body panels; that is, nosepieces that mimic the factory design, although they can be made of lightweight materials. This is all well and good until you’re trying to draw massive volumes of air into a supercharger’s inlet that isn’t efficient when it’s sucking hot underhood air. That’s where the inlet bells come in – they work to straighten out the airpath in these situations. The inlet bell is especially effective on side-slinger applications.

“If you have frontal air entering the supercharger, you need one of our bells. If you have a really good funnel on the front of the car directing air into the supercharger, the bell is of minimal improvement. Regardless, the internal modifications still provide a great gain,” says Morris.

Shown above is a variety of the bell designs including a restrictor bell for race classes that require limited inlet dimensions.

“I started designing the bells by making fiberglass molds, trying shapes, radiuses, tapers, things like that,” says Morris.

“They aren’t a simple radius; they are complex, and we incorporate four different radiuses into each bell—it’s not just a round entry inlet.”

Similarly to the internal ProVolute modifications, SME spent dozens of hours during the development process to determine how the inlet would work best. They even tried raised fins rather than machined-in grooves, and other designs. The trial and error netted the final design. Carbon fiber construction was also tried during the design process, but Morris says that due to the complex shapes used in the bell design that they were very difficult to replicate on a consistent basis.

The idea behind the grooves machined into the front of the bell comes from an interesting place—the aerospace industry. Morris says that you’ll often see these machined into the inlet of a jet turbine.

“We smooth out the inlet air with our bell, and we smooth the outlet air as it comes off the impeller with our internal modifications. One is for air coming in, and one’s for air going out,” he says.

Dyno Testing And Real World Input

Morris and his team spend an insane amount of time on the dyno at their shop; virtually every engine package that goes out the door gets to hit the 3,000-horse capable measuring stick before being delivered to the customer. One thing that Morris firmly believes in is the ability to prove out the performance of his company’s builds, and as you can see from the multiple videos linked in this article, the ProVolute series of modifications is no exception.

According to Morris, on the smallest ProCharger tested—the D-1SC—the internal modifications alone picked up a solid 71.8 horsepower and 66.3 pound-feet of torque, along with nearly a 1.5 psi increase when tested on a blow-through 572 cubic-inch big-block Chevrolet through an air filter. Over 1,100 horsepower was measured on the SME dyno.

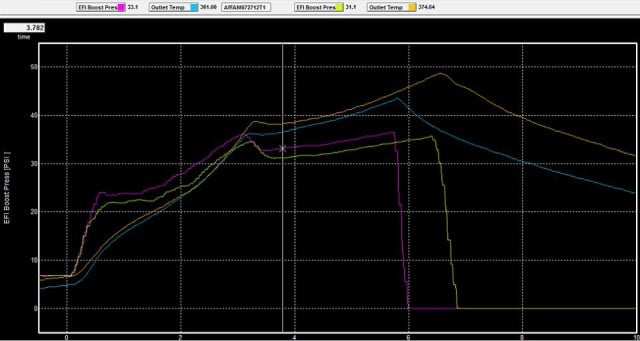

In one of SME’s internal tests on a 540 cubic inch big-block Chevy equipped with an F-2 in a pump gas/blow-through configuration. With the modified volute and ProVolute bell installed, they saw 1,322 horsepower and 955 pound-feet of torque at 7,300 rpm, with only 14.4 psi boost pressure. They then tested the same engine in the same conditions without the inlet bell. With the bell removed—remember, this is a side-slinger application where the supercharger’s inlet is just above the header—the engine produced 1,262 horsepower and 907 pound feet. There was also .6 psi drop in boost pressure without the inlet bell.

ProVolute Before/After ProCharger F-2 Testing

West Coast 275 racer DJ Reid has tested the ProVolute F-2 modifications in back-to-back passes on his ProCharged Camaro. The passes were made on the same day, within one hour of each other, and nothing was changed other than installing the ProVolute system.

“We ran pass one, removed the stock volute and then installed the Morris volute. We then ran pass two. We saw a 2-3 psi boost increase and a 10-15 degree temperature decrease across the board. Performance wise, we dropped from 5.17 to 5.03 and gained 2 mph,” says Reid.

In this overlay graph graciously provided to us by racer DJ Reid, we can see how the boost pressures with the ProVolute mods were up 2 psi (magenta trace) and the outlet temperatures were reduced (blue trace) over an unmodified supercharger.

Longtime Outlaw Drag Radial racer Will Stevenson also ran the ProVolute system on his recently-sold Third-Gen Camaro that was equipped with one of SME’s 615 cubic inch short blocks and valvetrain packages, topped with Stevenson’s previously-existing Big Chief cylinder heads. On top, he ran the ProVolute system with an F-3R 139mm for a number of years with excellent results from the system compared to an unmodified F-3R.

“It definitely picked up power; installing the ProVolute bell was good for about 1.5 psi boost as it helped to clean the air up. When Steve dyno’d my engine, he ran several different blowers on it and the ProVolute was the best one by far,” says Stevenson.

In Conclusion

As mentioned up above, Morris and his team prefers (prefer) to do lots of internal testing with the products and services they offer. This ensures that when the customers receive the products—whether it’s a modified supercharger or a complete engine package—it performs as advertised or better in the field. As we can see from the results peppered throughout this article, there’s no doubt that the ProVolute series of modifications deserves strong consideration.