When it arrived on the Mustang scene for the 1996 model year, the modular engine family presented several hurdles to Mustang owners, engine builders, and aftermarket parts suppliers. Though they were initially dismissed by many as being expensive, complex, and unworthy of major engine projects, today the modular engine is an extremely popular and cost effective platform. And without the first generation mod motors we wouldn’t have the performance capability of the current Coyote 5.0, GT500 5.8, or Cobra Jet 5.0.

To find out more about what goes into the design and manufacture of aftermarket pistons for performance oriented Mustangs we turned to three companies manufacturing modular pistons, MAHLE, JE Pistons, and Diamond Pistons.

Design

As technology has improved so have the offerings in OEM pistons. A new engine’s pistons are carefully engineered and high tech components. “Newer OEM pistons have a lot of high tech features,” says Trey McFarland, from MAHLE, “selecting just any off the shelf piston for a modular application can be a mistake.”

According to McFarland there are three critical factors to consider in high performance modular piston design:

- Emission concerns (blow by, oil control, pre-ignition)

- Short cylinder length

- Forced induction is power adder of choice for this engine family

Performance customers have changed through the years as well and what might have been acceptable levels of noise, vibration, and harshness (NVH) may be unacceptable today. This holds true in the aftermarket as well as at the OEM level. It seems every week we hear of another 700-plus horsepower car that is being daily driven. The modern performance customer not only wants high power numbers but wants to be comfortable making that power.

You have to look at all the aftermarket parts that go with a piston to make sure the part can fit multiple applications. -Nick Diblasi, JE Pistons

This makes selecting the proper piston for a customer somewhat of a balancing act. Many pistons that perform well in a hardcore racing environment may be ill suited for street going cars that only see occasional track duty.

Nick Diblasi from JE Pistons says that when coming up with a piston design, “You have to look at all the aftermarket parts that go with a piston to make sure the part can fit multiple applications.” JE is soon to release a new line of modular pistons, which Diblasi says will give the company 150 on the shelf part numbers for virtually every modular engine combination imaginable.

Diblassi also pointed out several areas in piston design that play a role in modular pistons. “With modern engines you have to worry about pin offsets, having the right cam and barrel shape on the skirt for stability.” He also added that these days everyone is looking for lightweight pistons. “Whether it holds a lot of boost or nitrous, it needs to be really strong, but light. It used to be you took the Nitro approach, made everything big strong, and heavy, but not anymore.”

Aside from these differences Ron Beaubien of Diamond pistons tells us that modular designs are fairly straight forward because the engines have been on the market for so long. With the modular engine now having more than 20 years in service, and 17 years in high performance applications, much of the initial r&d was done long ago in terms of what does and doesn’t work in a modular engine platform, and what the foundations are of piston design.

JE Pistons sent us these images from the computer modeling of their new line of Modular pistons.

Valve Pocket Design

One notable feature about all of the 5.4 and 4.6-liter engines are that the pistons are identical in dimensions. The 5.4 uses a taller deck block and longer rod to achieve greater displacement, but it’s bore diameter is the same as the 4.6. The pistons themselves are typically identical in physical dimensions with the exception of the valve reliefs cut into them for their particular application making them specifically a two, three or four-valve design.

Wrist Pin Trickery

With a modular engine, the small diameter bore is of less concern than is the bore length. The bore depth of a 4.6 modular engine is a short 90mm, which presented several challenges initially designing aftermarket pistons.

According to McFarland, one of these challenges in particular is the bore for the wrist pins. While not visible to the naked eye, at the OEM level the wrist pin bore is offset from the factory in all modular engines, including the current Coyote, Roadrunner, and Trinity engines. The reason for this says Diamond’s Ron Beaubien is, “The Modular engine is inherently noisy, if you make the wrist pin bore straight up the pistons knock. So the pin is offset to give it more positive thrust until it gets up to temperature. This reduces wrist pin slap or knock when cold.”

The wrist pin bores in modular pitons are slightly offset to give some positive thrust and while still allowing the pin to rotate. Diamond and MAHLE both stressed the importance of this in the reduction of NVH.

This slap is more noticeable according to McFarland because at the bottom of the bore, a portion of the piston comes out of the cylinder bore, exposing areas of the piston that are not normally out of the bore on other engines.

While a racer may not mind an engine that makes a bit of noise on cold starts, the enthusiast driving his car to work every day likely won’t want the engine sounding like it’s spun a bearing every morning or each night when firing up the car for the long drive home. This makes duplicating the offset wrist pin bore imperative to meeting the NVH requirements of many street enthusiasts.

The Modular engine is inherently noisy, if you make the wrist pin bore straight up they knock. So the pin is offset to give it more positive thrust until it gets up to temperature. -Ron Beaubien, Diamond Pistons

According to McFarland there are some other advanced features machined into the pin bores of many OE pistons that require special machinery, which MAHLE manufactures in house to support such advanced designs.

MAHLE machines a trumpet shape as the wrist pin bore progresses from the outside of the piston towards the inside near the rod. This allows the wrist pin to flex during the heavy inertial loads that occur at the direction changes, but still be able to spin. “If you stop the pin from spinning you run into loading and galling issues,” says McFarland. By profiling the wrist pin bores, the pin is able to spin and flex freely, continuing to distribute lubrication and reducing the possibility of galling. Wrist pin distortion that can also restrict the wrist pin’s ability to rotate as the rod and piston move through the bore during the combustion cycle is an issue as piston speeds loads increase. According to McFarland, MAHLE actually machines ovality into some wrist pin bores to allow for this pin distortion rather than increasing pin to piston clearance.

Rings

Rings are another area of particular challenges for Modular piston development. The small bore length creates the need for a short piston and short skirt area. Short pistons are nothing new, but as McFarland tells us, the OEM’s continue to move rings upward.

McFarland says this upward movement is done for a few reasons. The primary reason is for emissions purposes, as the rings move higher, the crevice volume decreases. Crevice volume is the gap area along the sides of the piston from the top of the piston to the first ring. This area can become filled with gasoline droplets, which can ignite causing crevice volume detonation.

Get Coated

Piston coatings are nothing new in the world of high performance. From basic Teflon® skirt coatings to reduce friction, to ceramic piston top coatings for increased durability and heat transfer, these coatings have made the transition from high end race only, all the way down to the regular enthusiast, engine builder, and even OEM.

Hard anodizing reduces micro-welding in the ring lands. It also adds durability to the piston, as Beaubien tells us, “It also allows racers to get more aggressive on their tune up or run more boost without worrying about burning up the piston due to the anodizing.”

JE has recently come out with a new coating as well which we highlighted in our short block build for Wild E Coyote. JE says their Tuff-Skirt coating will not wear away and provides anti-friction/anti-wear as well as lubricating benefits.

According to McFarland, unlike typical detonation which causes a second flame front ahead of the piston, pushing against its motion on the compression stroke, crevice volume detonation actually pushes the piston sideways. This can push the piston and the rings into the cylinder wall, causing excessive bore wear and in extreme cases cylinder bore damage.

Moving the rings up on the piston reduces crevice volume detonation by reducing the crevice volume area, which also reduces vehicle emissions, NVH, and can prolong engine life. However, with the rings higher on the piston, the amount of abuse that piston can take over what it’s original design characteristics are is diminished. McFarland says, “Now the OEM’s are moving the piston rings so high, you’re starting to roll the dice on the power handling in terms of modifications over 50 horsepower.”

This is where MAHLE utilizes many of their years of OEM level experience. While they move the rings down on performance oriented pistons for modular applications, McFarland says in doing this they must bear in mind why the rings were moved up in the first place. Moving the rings down not only increases the possibility of crevice volume detonation but it also changes the emissions compliance of an engine and even the drivability. A ring package that performs well on the drag strip or road course, where the engine operates at high RPM, may not be well suited for a daily commuter that sits in stop and go traffic, and spends a lot of time idling, or is subject to emissions testing. All of these things must be considered when specifying a piston for a particular engine build.

Ring Placement

MAHLE manufactures their own rings, meaning that the rings they sell are matched precisely to their pistons. McFarland tells us, “The bigger challenge is marrying the flanking area of the ring to the floor of the ring groove.” The rings must lay flat in the groove to avoid blow by, which is where cylinder pressure escapes past the rings into the crankcase. Blow by not only wastes performance but also can cause emissions compliance issues, as well as gasket and seal failures.

Diamond manufactures their custom pistons using CNC mills. This means that they too can closely match the ring grooves to the particular piston that a customer orders, also packaging them as a set. “The ring grooves are cut to match the ring package that the customer has selected,” says Beaubien.

Micro-Welding

Now the OEM’s are moving the piston rings so high, you’re starting to roll the dice on the power handling in terms of modifications over 50 HP. -Trey McFarland, MAHLE

Micro-welding is a problem that is seen primarily with 2618 alloy forged aluminum pistons, that are subjected to high heat and stress, such as extremely high compression ratios, nitrous, or forced induction applications.

Micro-welding occurs when heat and pressure cause aluminum from the piston to transfer to the rings. According to McFarland once this process begins, it can cascade quickly into a major internal issue. “Micro-welding also causes more heat to remain in the piston because it can’t be transferred to the cylinder wall due to the aluminum buildup, once it starts going bad it happens pretty fast.” One of the ways to reduce micro-welding is with piston coatings.

Alloys

There are three primary aluminum alloys used in piston manufacturing, and modular pistons are no different. When ordering a piston for any engine it’s critical to have in mind exactly what the application requires. “Choosing what to make the piston from is a large challenge because how the piston is used is critical,” says McFarland. With such a wide variety of applications and power levels now available for modular enthusiasts, it is becoming increasingly difficult for piston manufacturers to simply stock part numbers, or take a one size fits all approach to piston manufacturing for one family of engines. “You struggle with putting a horsepower number to a piston in these instances because of varying boost levels, different heat levels, and other conditions,” says McFarland.

Hypereutectic

Cast hypereutectic pistons have several benefits in OEM applications as well as some performance applications. Most OEM modular engines with the exception of the extremely high performance models have been using cast hypereutectic pistons since day one, including the current Coyote 5.0.

According to McFarland hypereutectic alloys are highly resistant to expansion, and wear extremely well. This allows OEM manufacturers, or builders in the aftermarket to construct an engine with extremely tight piston to cylinder wall clearances since the piston will not expand enough to cause a problem. These alloys also have a high resistance to scuffing which improves their wear resistance. The biggest downfall to a hypereutectic alloy is its high silicon content. The high silicon content makes the piston more brittle, and under violent detonation, such as that which can occur when things go wrong in a nitrous or forced induction engine, these pistons can be catastrophically damaged.

Eutectic 4032

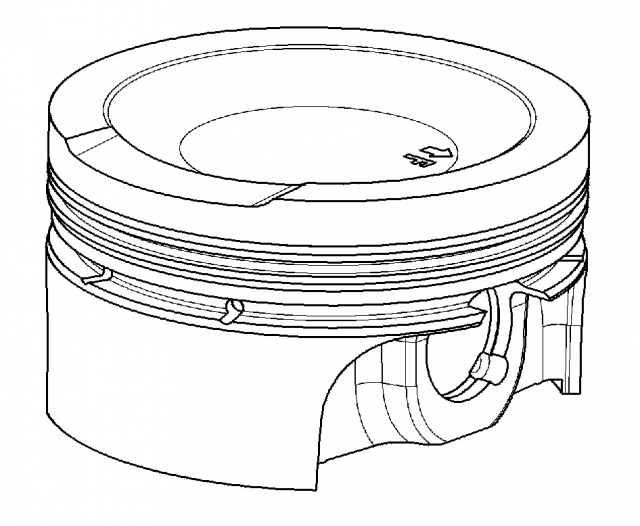

With new piston designs creating a physical model for test fitting and final design verification is a key part of the final design process.

Eutectic alloys should not be confused with hypereutectic alloys. 4032 is the most common eutectic alloy used in pistons. It does contain some silicon content, however it is much lower and more tightly controlled than in a hypereutectic piston. 4032 pistons are also forged, rather than cast, further eliminating the larger pockets of silicon found in many hypereutectic pistons.

According to McFarland these alloys don’t typically need hard anodizing for the ring areas or the rest of the piston, as they’re strong enough to resist micro-welding in many cases. They posses good wear characteristics, and McFarland says their combination of strength and wear resistance make them well suited for a variety of applications where a forged piston is necessary.

Many high performance engines run pistons with this alloy including endurance racers, forced induction applications, and even some OEM applications. “This is an ideal choice for modern engines with tight controls on the fuel system and ignition timing, where detonation is not an issue,” says McFarland.

2618 X-Material

2618 is the racer’s alloy, also known as X-material. This alloy contains no more than .25 percent silicon. It is strong, yet under heat and pressure it becomes malleable. According to McFarland that malleable characteristic actually allows the piston to distort under extreme conditions without fracturing, or failing. This can save other engine components during extreme detonation.

There are drawbacks to using 2618 pistons though. According to McFarland that distortion which saves the engine, may require the pistons to be replaced as part of periodic maintenance. We’re not talking about after every race, but where racers running a milder setup with 4032 alloy pistons might perform a ring and seal replacement between seasons, a racer with a 2618 alloy piston may need to replace their entire set of rings and pistons.

McFarland says this makes 2618 less than ideal for a street/strip application that sees more street time and only occasional track time, or for those applications where budget is critical over power production. All out race engines that see mostly dedicated track duty though are ideal candidates for 2618 forged pistons.

Not quite round

Because aluminum expands to some degree when heated, the shape of a piston may change as an engine goes through it’s heat cycle. This is where ovality comes into play. Pistons may be manufactured with a slightly obscure or oval shape. This ovality is precisely engineered so that as the aluminum heats and expands, the piston shape itself expands to precisely the correct shape for the cylinder bore. The advantage is tighter clearances at operating temperatures and better ring seal, as well as reduced friction. According to McFarland, MAHLE can even manufacture multiple ovalities into a piston depending on how the engine builder, or OEM manufacturer specified the shape of the piston needs to change as heat builds inside the engine.

While pistons generally look round when viewed with the human eye, MAHLE can machine ovality into their pistons that allows the aluminum to expand when heated for tighter piston to bore clearances.

The engineering and technology for modular engine components has been around now for over 20 years, with those engines first making their debut in the 1992 Ford Crown Victoria and Lincoln line of cars. While the OEM’s will continue to change piston design, many of the basic ideas remain the same. These leading companies MAHLE, Diamond, and JE will no doubt continue to update and improve their manufacturing and engineering practices to continue supplying high performance pistons for today’s high performance cars.