Today’s engines are intricately designed and engineered assemblies. Even in stock form, the horsepower and torque levels are staggering, especially for the duration we run them. And then we crank up the power levels up even further with aftermarket parts. It’s astonishing to think about the intense forces on the piston — the turbulent air, the rocking motion inside of the cylinder, not to mention high temperatures and extreme pressures. No wonder some parts fail.

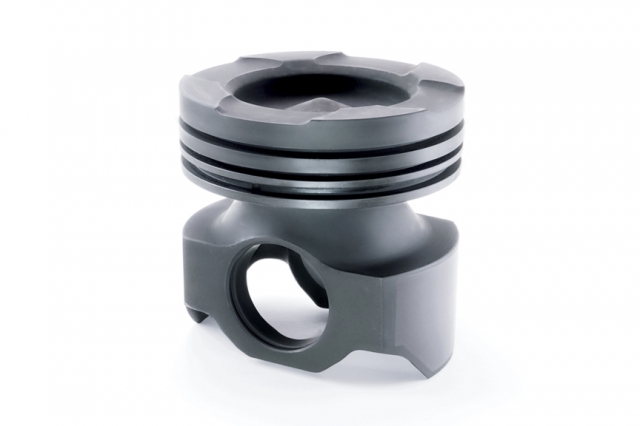

To help counter these destructive forces in diesel engines, Mahle Motorsports has developed the Monotherm piston. Engineers are not only providing details on this cutting-edge high-performance design, but they’re also helping our readers fully understand the piston’s rather punishing environment.

The Compression and Power Stroke

Most common rail injectors operate between 3,000 psi and 30,000 psi. Most mechanical injection system will operate between 3,000 psi and 20,000 psi.

As the crankshaft rotates, the rod and piston are pulled downward, creating a low pressure area inside the cylinder. This low pressure area is filled with the boosted air that flows through the intake manifold and past the intake valve. After the piston hits bottom dead center (BDC), the momentum and force is reversed. This change in direction thrusts the piston against the cylinder wall. As the piston moves up, it compresses the air, not only reducing the volume in the cylinder but also heating the air. Before the piston reaches top dead center (TDC), the fuel injector sprays fuel into the cylinder under very high pressure to promote atomization.

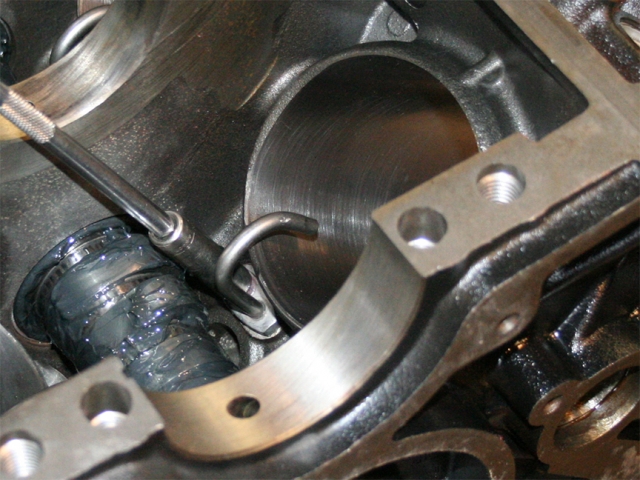

As the piston reaches TDC the fuel ignites and the combustion begins, even as the fuel continues being sprayed into the cylinder. Again, the piston is forced against the cylinder wall. The fuel and air continue burning and creating intense pressure on the piston as it moves past TDC and resumes a downward path. Shortly into the power stroke, the fuel stops spraying but the burn continues. Soon, oil squirters positioned below the cylinder begin cooling the bottom of the piston with an upward spray inside the piston.

Oil squirters are used to spray oil to the underside of the piston. The oil helps to remove heat from the piston after combustion, preventing the pistons from failing.

Factory Pistons

The factory cast aluminum pistons are designed with steel ring grooves to help withstand the cylinder’s harsh environment. However, as truck owners increase power levels, and therefore the cylinder pressures, factory pistons could fail.

“The Cummins is actually an industrial engine,” explains Trey McFarland of Mahle Motorsports USA. “So, the stock components in that motor are way overbuilt for what that motor is being asked to do in a light duty pickup truck. Whereas the others, the Ford and GM are motors built around a light-duty pickup truck and are subject to failure a little sooner generally. The issues are still the same.”

It is no coincidence that these cracks line up with the fuel spray pattern. The fuel in modern engines actually erodes the piston away. This creates thin spots that are prone to cracking and failure.

Issues with Factory Pistons

Issues with pistons can be broken down into two categories; pre-common rail and common rail.

“Basically the way the guys with non-common rail engines are making power, other than the camshaft and some other things, is that they put lots of fuel into them. That kind of fuel generally raises exhaust temperatures considerately and that seems to be what ends up tears them up. If someone gets too aggressive with the tune and doesn’t understand what all is going on, they just cook the thing,” explains McFarland.

A common rail engine can still be over fueled and similar problems can surface. Most of the tuners are realizing that more power is available without heavily over fueling the engines.

“Exhaust temperatures are still the killer of common rail engines, but there is another issue and that is erosion from the fuel injector itself that has been causing a lot of the issues we see in the aftermarket,” adds McFarland.

“In stock form the bowl and top of the piston are designed to have the fuel spray right into the bowl, right before the piston reaches top dead center. Newer bowls have what is called a re-entrance bowl. The whole point (the hope) is that any fuel that doesn’t light on initial injection goes back into the flame front and burns. It doesn’t make any more power, it just burns cleaner and that is the deal,” continues McFarland.

When adding power, the injector pulse width usually is increased. The longer the pulse width, the earlier the injection event usually occurs.

“So instead of spraying fuel into the bowl, the piston is now coming up to top dead center through the spray. It is then dragging the spray across the rim area at the top of the bowl. With rail pressures close to 30,000 psi, high temperatures and high pressures, the piston erodes. It actually eats the aluminum away,” says McFarland.

Performance Cast Pistons

The factory cast piston is a durable design. A significant number of trucks run factory pistons well over 200,000 to 400,000 miles with no issues. Which begs the question of how to achieve that durability from a high-performance piston? Engineers start with the same cast piston, then address the issues the aftermarket imposes.

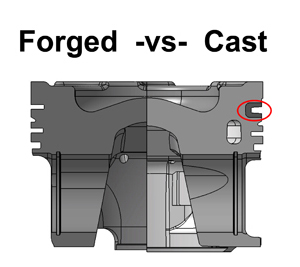

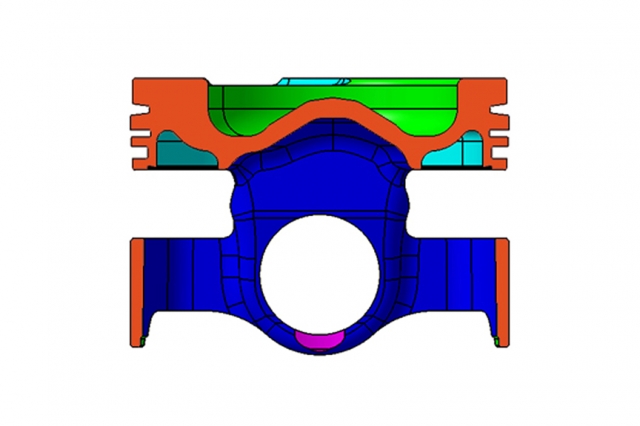

In the cutaway, you can see the oil gallery that is just below the crown of the piston. Also, notice the two different materials at the top ring. The steel insert extends piston life by keeping the ring sealing longer.

“We cannot change that those injection pressures under those conditions are going to erode aluminum,” says McFarland. “So, our Performance Cast Pistons are machined factory style pistons. We machine them with less or no re-entrance bowl. Basically, we increase the cross sectional area considerably and make the leading edge much more blunt. Therefore, it is much harder for erosion to start– and even once it starts it moves much slower.”

In addition to modifying the shape of the bowl, there are a couple of changes that aren’t seen by the naked eye. Factory pistons usually fail due to insufficient cooling. This is caused by the erosion thinning out the material between the cooling jacket and the surface of the piston or the piston cracks into the cooling jacket. Mahle piston cooling jackets have been moved due to the larger bowl design to increase the durability.

Mahle also utilizes coatings to help reduce the heat absorption characteristics of the pistons.

“The cast pistons that we offer are 750-800 horsepower type pistons. Once you go beyond that, you are going to be pushing the cast parts pretty good,” warns McFarland.

Performance Forged Pistons

Another option for a high-performance engine is a forged aluminum piston, which is more durable than a cast piston. The forging process packs the metal grainscloser together, so cracks are much less apt to form, or propagate if one starts. Also, the continuous nature of the grain structure helps ensure a stronger piston.

Unfortunately, forged aluminum pistons don’t have a steel ring groove. After a period of time these pistons may need replacement due to ring failure. How long will they last?

“Basically, just watch your blow-by. The blow-by tells you when your ring grooves are wearing out,” recommends McFarland. “The piston isn’t going to come apart, the ring grooves just won’t seal any longer. On the extreme side of things, we have a guy that has forged pistons and he tows a trailer with four or five cars all around the country to different shows. Last report I got, he was at 70-plus thousand miles and everything was fine. The motor runs about 700 horsepower, and he runs it pretty hard. He doesn’t race it but he is always hauling with it. Then on the other side of things, we have reports of guys going out and doing five pull nights and then say they have tons of blow-by. So, there is really no clear answer other than to recommend people watch their blow by.”

“Basically, just watch your blow-by. The blow-by tells you when your ring grooves are wearing out,” recommends McFarland. “The piston isn’t going to come apart, the ring grooves just won’t seal any longer. On the extreme side of things, we have a guy that has forged pistons and he tows a trailer with four or five cars all around the country to different shows. Last report I got, he was at 70-plus thousand miles and everything was fine. The motor runs about 700 horsepower, and he runs it pretty hard. He doesn’t race it but he is always hauling with it. Then on the other side of things, we have reports of guys going out and doing five pull nights and then say they have tons of blow-by. So, there is really no clear answer other than to recommend people watch their blow by.”

The Steel Option!

These pistons are what enabled the over the road truck manufacturers to start offering million mile warranties – Trey McFarland

“Ferrotherm is a two-piece piston that had a steel crown with two skinny pin boss hoops, and an aluminum skirt that slipped in. The pin holds the whole thing together. That combination isn’t really a good combination for high rpm. So, we designed the Monotherm, which is made out of one material,” says McFarland. “It is a chromoly steel, and these pistons are what enabled the over the road truck manufacturers to start offering million mile warranties. They can achieve that because these steel pistons are way overbuilt for what they are doing.”

The Monotherm piston was introduced commercially in 2000 and has proven extremely durable with millions produced.

The Material Advantage

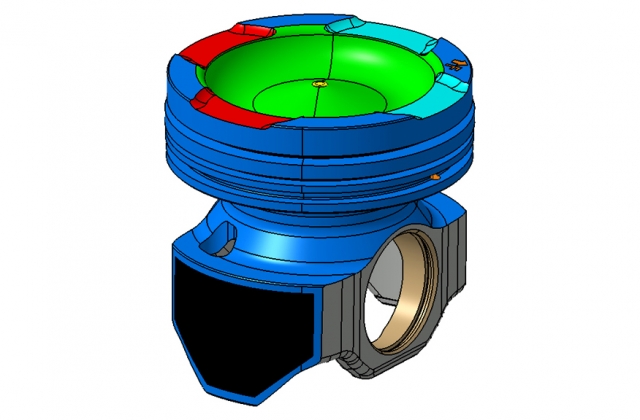

“In the Monotherms, you have your steel ring insert because the whole piston is steel. Then there is a cooling gallery, like the aluminum pistons, to help pull temperature out,” says McFarland. “With today’s cylinder pressures, temperatures, and fuel injection rail pressure, we aren’t at a point where steel will erode. I doubt that we will ever be. So eroding isn’t an issue with these steel parts.

Since the pistons are of a similar material as the cylinder, both have similar growth characteristics. That means engine builders may not need extra clearance required with an aluminum piston.

“Mahle Motorsports in general will run tighter tolerances than our competition. A lot of that has to do with controlling the growth of the piston and the shape of the piston as it grows to operating temperatures,” says McFarland. “If you cannot control the growth characteristics of the piston, then the answer for years has been add a little more clearance to it. When you get to a steel piston, running extra clearance isn’t a good idea. You basically start bashing that bore with an anvil, and it will beat the hell out of the block.

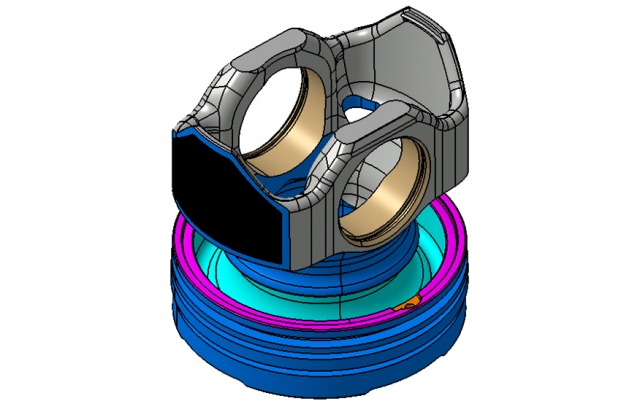

Notice the huge oil galley under the crown. Normally, this area isn’t seen because there is a cover that keeps oil in, but in this CAD image; the cover has been removed.

“As the piston sees more heat, it will grow more than the cylinder because it doesn’t have the heat sink properties that the cylinder does. There does need to be some clearance but we have built a profile into the piston. When you order up a steel Monotherm piston for a 4.100 bore, you need to be putting it in a 4.100 bore hole,” stresses McFarland. “If you want to make it 4.105 or anything else, then that is your choice. It doesn’t take much to get to a point where it is abusive on the parts. So it is a little bit of new thinking for a lot of the guys out there.

“If you run a little bit of a tighter clearance, the wear goes the opposite direction and comes way down,” sums up McFarland. “The tighter clearance keeps the piston from rattling around in there. It is being supported up against the bore by the face of the rings, and the skirt coating that we put on the skirts. That is where we get the million mile warranty for the over the road truck stuff. Now that doesn’t go for the race stuff, but they will last.”

Weight

With steel being much stronger than aluminum, the Mahle Engineers were able to create what many would consider an odd looking piston. These large funky shaped holes help to reduce the weight drastically.

With steel being much stronger than aluminum, the Mahle Engineers were able to create what many would consider an odd looking piston. These large funky shaped holes help to reduce the weight drastically.

“If you look at it, it looks like it has so much less mass than an aluminum piston, which it does. So, some people think it is lighter. In fact, it is heavier than its aluminum cast stock piston, but we gain a lot of the weight back with the pin,” says McFarland. “In most cases, the Monothterm piston and pin combination compared to the stock piston and pin combination is within 100 grams of the same weight. So when we are talking about 1,300 – 1,400 gram pistons, it isn’t grossly overweight. When you feel the piston and look at it, it just looks like something that should be lighter weight.”

Another unique characteristic of the piston is the weight is focused toward the crown. So, many times when someone picks up the piston, they suddenly believe it is way heavier than it actually is, because it is so top heavy.

“We don’t have a lot of mass below the ring belt. This is the case with most of our pistons but the unique design of the Monotherm emphasizes this more. This is one of the ways we can control the growth of the piston and how it comes up to full operating temperature quicker. Those are key in the steel piston,” adds McFarland.

Durability

“One of our Bonneville guys broke a rod and windowed the block. The rod caught the piston, bent the skirt aggressively, and kicked the piston sideways in the bore pretty good. Tore that cylinder up real good but they were able to move everything except for what was in that cylinder over to another motor,” says McFarland. “They reused the crank and the other five rods and pistons. If that was an aluminum piston, it would have come apart and trashed the whole motor. We had another guy who was regularly running 2,300 to 2,400 EGTs for an entire season. He cracked two blocks and just moved the pistons over to another engine both times. We have had a couple of our testers run the pistons up to 6,000 rpm.”

In addition to the mechanical benefits of the pistons, Mahle Motorsports treats the pistons to ensure extra durability. There’s a phosphate coating to help with lubricity for the rings and pin bores, and it helps guard against rust. The skirts are also coated with a Grafal skirt coating that offer anti-friction and cushioning properties.

“It helps quiet the motor down and eats up some of that abuse that you normally get at top dead center and BDC,” adds McFarland.

The 6.7 Cummins Monotherm should be available sometime this summer, and Mahle is working on Duramax applications.

“The Duramax poses a little bit more of a challenge. It is a lot shorter compression height and we are experimenting with a few different designs,” says McFarland. “The challenge is trying to come up with a design that is cost effective.”