The Chevrolet big-block engine has undergone a myriad of developmental changes throughout its long life; the 396 cubic-inch version was introduced in the 1965 Corvette as the L78 option, along with an appearance in the Z16 Chevelle as the L37 option.

From the factory the engine used a 4.094-inch bore and 3.760-inch stroke to produce 375 horsepower along with 410 lb-ft of torque in this configuration. These are respectable numbers, but as you’re about to find out, there’s plenty of room for performance improvement when a solid arrangement of parts is selected.

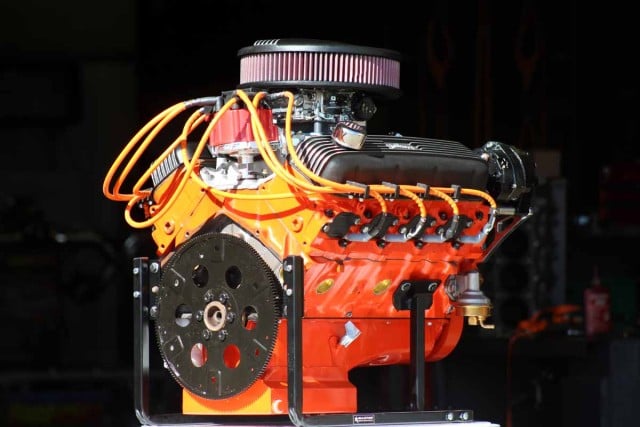

“We’re making really good power with these older, smaller engines. This 396 made 468 horsepower, which puts it at more power than the first two levels of the 502 GM crate engine, and the price point is right,” says Borowski’s Ken McCaul. “The engine looks the part, also.”

The stock 396 block and crankshaft were machined to Borowski's specs and re-used in this build. They also added a set of ARP's 3/8-inch connecting rod bolts and an octet of AutoTec pistons to finish off the rotating assembly.

Illinois resident Calvin Carter just so happens to be the owner of one of these “small” big-block engines, and recently dropped it off for McCaul, Dave Livesey, and the guys at Borowski Race Engines, Inc. in Illinois to have their way with it.

Carter has a numbers-matching 1970 Chevelle SS that the engine came from; it will find a home back in that vehicle when its restoration is complete. Between now and then, he actually has plans to install the engine into a 1956 Chevy that he’s owned for a while as a stopgap measure – and to get the engine broken in.

The story behind the Chevelle, however, is an interesting one. “I’ve only owned the Chevelle for about a year now,” says Carter.

“The original owner went through a nasty divorce and had the car sitting outside next to a two-car garage. He built three walls and a roof that connected to the garage and enclosed the car so that you couldn’t even get to it unless you busted one of the walls down. It sat there for almost nineteen years while he was going through this divorce before he sold it to me. This is one of the cars I’ve always wanted.”

When the car was parked, the engine had been hurt and was out of the car sitting in storage, and when Carter acquired the works, he needed to go through the entire package to return the engine to its former glory.

There’s nothing special here in terms of unobtainium parts – just a well thought out combination that stomps the dyno with 468 horsepower.

That’s where the Borowski crew enters the plan. Using the original factory block, factory cast crankshaft, and connecting rods, they then spec’d out a set of Autotec pistons complete with a 1.5mm/1.5mm/3mm ring package to arrive at a street-friendly 9.25:1 compression ratio, good for Carter to pull up to the pump and hook up his big-block with regular old 93 octane fuel.

The hydraulic roller camshaft, timing set, and aluminum roller rocker arms are among the valvetrain pieces supplied by Howards Cams. The camshaft grind used in Calvin Carter's big-block is just one of many that Borowski keeps on the shelf. Borowski's Ken McCaul raves about the performance of the company's camshafts and says they are a big reason why Borowski's engines perform as well as they do.

A combination of Clevite main bearings and King connecting rod bearings are used, as in this particular application the Borowski team has found them to perform best. The connecting rods have been upgraded with 3/8-inch ARP bolts that offer plenty of clamp load for this application. ARP’s head bolts are also used.

The stock connecting rods were reconditioned and should provide years of service in this application.

A full complement of Howards Cams valvetrain gear is used from the cam to the roller rocker arms and everything in between.

The camshaft is Howards’ 121906-08 hydraulic roller grind, and carries specs of .601-inch lift across the board with 233 degrees of duration at .050-inch lift on a 108-degree centerline. Howards 1.7:1 roller rocker arms are also on board, along with a full set of Howards hydraulic roller lifters to offer solid performance and long life. One of Howards’ double-roller timing chains was also used.

Fel-Pro 1212 intake gaskets and stock-replacement, .039-inch-thick head gaskets seal up the innards, which are topped with a set of iron factory cylinder heads.

“We did a bit of bowl work on the cylinder heads on this engine, and it really impressed us on the dyno for an iron-headed engine,” says McCaul. Picking up nearly 100 horsepower over the 396’s factory horsepower rating was no easy feat, especially considering that no changes were made to increase the engine’s displacement.

A Moroso oil pan, pickup, and oil pump finish off the assembly, which will be located between the framerails of Carter’s Chevelle sometime later this year – and that’s where the rest of Calvin Carter’s unique story comes into the picture.

The retired Chicago Park District employee and musician (he plays drums) has started a new endeavor – opening a shop in Blue Island, Illinois, called Mach One Mentoring, to teach youngsters the finer points of vehicle restoration.

“We’re teaching kids the skills of mechanical service, auto body, and restorations – and that’s where I’m going to restore the Chevelle,” says Carter.

“We just got approved in March for our 501 (c)(3) designation. What we’re teaching is safety first, how to take a car apart piece by piece, catalogue it, inspect parts for function, and even fabricate new parts.”

Factory cylinder heads are used and have been treated to some mild portwork. Here you can see the Howards roller-rockers in all their glory. It’s a shame these get covered up!

The intent of the school is to help get Chicago’s youth into a profession where they can earn a respectable living.

“I plan to reach out to some of the kids I used to work with and bring them into the mentoring program and get them off the street. They are stuck in the terrible living situations and don’t know how to get out of it; I want to give them an opportunity to do something different and succeed,”he says.

The target is not just inner-city kids; Carter tells us that anyone who wants to learn how to restore cars from bumper to bumper will be able to find a home at the mentoring program.

Doing something positive for the community–especially one as hard-pressed to find positive role models as Chicago is–shows that Carter and his colleagues are resourceful and have a solid plan. His positive spirit comes through quickly in a telephone conversation, leading us to believe that he’ll succeed.

“If you want to learn, we’ll teach you,” he says.

We can always use more automotive enthusiasts–especially ones that are willing and able to take on the challenging task of restoration. It’s nice to see what Calvin Carter and Borowski Race Enterprises have done with this engine to get it back up to speed; the engine has an exciting future!