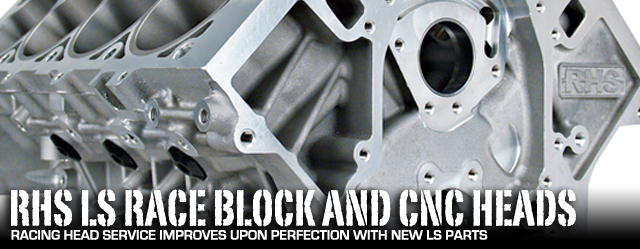

Professional engine builders and performance enthusiasts have long been familiar with Racing Head Service (RHS) out of Memphis, Tennessee, and the word is getting out on the street more than ever. As the aftermarket broadens their reach to appeal to more enthusiasts, RHS wanted to be in front of the curve by providing the late-model GM lover with their new LS platform offerings that exemplify RHS’ fame for superior heads and valvetrain components.

RHS is no stranger to eking out the most performance from cylinder heads, dating back to their first year in 1967, when RHS began manufacturing its own racing cylinder heads. Since then, RHS has grown into a key member of the aftermarket industry, providing everything from complete turn-key engines to key components to building your own performance-bred powerplant.

Making their reputation with a successful line of cylinder head designs and porting techniques, RHS launched Competition Cams, which has grown to become one of the largest entities in the aftermarket industry.

Innovations in the new LS Race Block are readily apparent, particularly to the LS enthusiast who knows where to look. The Race Block comes already prepped for a dry sump oiling system, gussets for a variety of motor mounts, enlarged lifter bores, under-piston oil squirter provisions, and notches for added rod clearance.

Not a Chip Off The Old Block, But a Whole New Block

LS RACE BLOCK:

- Machined from A357-T6 aluminum alloy

- Standard (9.240”) or tall (9.750”) deck height, and clearance for 4.600” stroke

- Bore sizes 4.165” or 4.125” (501cid or 492cid)

- Thick decks: .500” standard; .750” tall

- Cylinder sleeves available in standard (5.87”) and tall (6.38”); matching liners available

- Better pushrod geometry (<2° maximum pushrod angularity using standard deck height) by raising camshaft centerline .388” (requires 2-link longer timing chain, available from RHS as P/N 3154); tunnel will accommodate stock; will accept oversized (e.g., 60mm diameter roller bearing camshafts) with machining: standard (.842”) lifters, with material available for 1.060” bushing for keyed lifters. (Already machined and microfinished for standard 55mm cam)

- Side oil galleys shifted outward for clearance; also reduces windage; provision cast-in for piston oil squirters

- Dry sump friendly; AN-12 front and rear side feeds

- Uses stock water pump; machined for Gen III and IV knock sensors

- Increased side window area, compared to LS7/LSX engines

- 6-bolt head design with full water jacket (as per LSX design)

- Billet main caps; maximized main cap mating surface for maximum support; can accommodate up to a ½” diameter fastener

- Rolled threads on all threaded holes – precision and strength

- Includes Gen III and IV compliant; includes “factory” and “motor plate” race mounts for Gen I, II, III, and IV engines.

- Part Numbers:

Tall deck (.750” deck thickness), 6.38” liner, 4.165” honed bore; (501cid) 120 lbs: P/N 54900

Tall deck (.750” deck thickness), 6.83” liner, 4.125” honed bore; (492cid) 124 lbs: P/N 54901

Standard deck (.500” deck thickness), 5.87” liner, 4.165” honed bore; (501cid) 111 lbs: P/N 54902

Standard deck (.500” deck thickness), 5.87” liner, 4.125” honed bore; (492cid) 115lbs: P/N 54903 - Block Price, all: $5082.00

Being such, RHS has been paying attention to all the innovation going into GM’s LS engines over the past few years. To meet the swelling of technology and performance coming out of the LS motors, RHS recently designed a fresh take on the LS engine block for extreme street and racing applications.

You can tell there’s been a lot of thought put into the new RHS standard and tall-deck blocks. Because builders have different cam preferences, the camshaft tunnel is large enough to accommodate even 60mm roller-bearing camshafts; lifter bores take .842″ lifters, but can accept a 1.060″ bushing, for keyed lifters.

To that end, they developed and now offer a large selection in their LS Race Block series in several bore diameters and deck heights. Made from A357-T6 aluminum alloy with spun-in cast iron liners, the new RHS blocks have plenty of room inside, for counterweights and longer-stroke racing and deep-breathing street applications. Extra material is deliberately included, to allow a degree of custom machining. (It’s always easier to remove metal than to add it!)

Kevin Feeney, Product Manager at RHS, says, “The LS market is growing, and the LS components have been some of our biggest sellers – cams, lifters, heads. We chose to build a block because there simply was not a good alternative. Some guys are building 2000hp+ engines, so we especially focused on adding strength.”

The plan was to include the features and benefits that an engine builder would want in an all-out race application (i.e. tall deck, big bore, long stroke, dry sump friendly, race motor mounts and ability to go to larger cam cores and lifter diameters). “However,” says Feeney, “we also wanted to ensure that it had all of the accessory bosses and motor mounts for a Gen III or Gen IV application and could bolt into a late model car.”

Bigger Than Life Dimensions

Bigger, one could (and often does) argue, is better, and engine builders keep looking for ways to increase bore and stroke. The RHS blocks have a taller deck to accommodate up to a 4.6″ stroke, and a different liner and water jacket design to overcome the bore limitations imposed by the 4.4″ bore centers. Ready-honed blocks are available to 4.165″ bore. Yes, if you do the math, you’ll find 500-plus-cui potential.

Builders needed a more-accommodating block, Feeney realized, because he saw that some LS owners “were machining out the entire decks, just to get a better liner. Others machined and added a deck plate. All that machining is extremely expensive.” In the case of the factory block this is further complicated by the use of a cast in liner which really limits the bore size.

To get around this, some engine builders have been boring out the factory liner and installing aftermarket liners to maximize the bore size. “With this in mind we designed our block from the beginning using a press in cast iron sleeve that can be opened up to 4.165″ in still maintain a .095″ material in the siamesed section.”

Then, “When you install a longer stroke into a stock block either shorten the rod or the compression distance of the piston (or in most cases a combination of the two), you also begin to pull the piston out of the bottom of the cylinder bore, which the factory addressed in the LS7 block by installing a longer liner. That helped on that end, but the stroke was still limited by the deck height.”

Exceptionally strong and significantly lightweight, RHS is out to prove that its new Race Block is in fact, a large improvement on what many already deem as perfection.

After looking at what builders wanted to do and what was available, RHS realized that the block he envisioned and wanted simply didn’t exist, so “This was a clean-sheet design. We designed it around the taller deck, with a longer stroke. We put all the features and benefits of an all-out race block in there – we can accommodate bigger cams; and the 357 alloy is extra-strong.”

“So, we decided to raise the deck from the stock 9.240 to 9.750″ specifically to accommodate fitment in the new Corvette and Camaro without having to modify the cowl area of the vehicle. We also raised the camshaft .388″, which is the next limitation for a long stroke.” This, he points out, requires two more links in the cam chain. Not a big deal, but it’s good to know! “We also moved the main oil galley outboard to clear up to a 4.600″ stroke with a 2.100″ rod pin.”

“We really designed an ultimately 500cui, 2000+hp race block,” he said, “but we wanted also to accommodate regular people. That’s why we have Gen III and Gen IV engine mounts, and accommodations for the knock sensors.”

[9]Strength, though, was #1. “One of the features we really enjoy is the 6-bolt head pattern, as GM used on their LSX block,” which, he noted, “weighs more than twice as much as an aluminum block.” The blocks are actually cast in the UK, at Grainger Worrall, the Cosworth foundry. “They have the expertise and the quality we wanted.”

[9]Strength, though, was #1. “One of the features we really enjoy is the 6-bolt head pattern, as GM used on their LSX block,” which, he noted, “weighs more than twice as much as an aluminum block.” The blocks are actually cast in the UK, at Grainger Worrall, the Cosworth foundry. “They have the expertise and the quality we wanted.”

Much of the newness of the LS specification has worn off, and “Some of the older LS engine builders have really embraced it. Some of the ‘traditional’ builders are a little scared of the LS platform, partly because of the longer skirts; but GM addressed those [windage] issues, and we’ve even improved on them.” Is the block being accepted? “We’re amazed at how many people are taking brand-new Corvettes — street machines – and swapping out their engines for these.”

It’s not too hard to do, really. Feeney says, “We furnish a honed, finished block. Most people will need no machining to build their engines, in their own shops.”

“We always have that mindset,” Feeney says. “If you’re developing an all-out race part, that’s fine; but our customers are a combination. Some guys want to buy all the parts and build their own; others have a full engine machine shop. We can take care of them, too.”

For instance: “If a customer has, say, a new Camaro or Corvette, he could actually buy our finished block and reassemble his old parts to it. Or he could make it a dry sump system – the fittings are there; the plugs are there. It’s his option. The block comes with front and rear plates.

Some machining may be required in super-long stroke setups, in the form of sleeve notching. RHS doesn’t want to do this automatically, due to the various configurations of internal parts that could go into their block, and also because, if you don’t need the notch, you get more skirt support.

It’s versatile, too. RHS offers plates for both ends, and they want to give builders whatever they need: “There are a few people are using our LS parts on the circle tracks.” [Feeney is a circle-track racer himself.] “They run a lot of things off the front cover; we don’t use the GM front cover, but we have specialized covers – we can run the distributor or dry sump pump off the front; we even have a gear-drive application.”

RHS' new LS3 and LS7 are just as calculated and revised as its race block.

How About the Top End?

The “Pro Elite” LS7, Rectangular Port Heads:

- Works in small and large cube configurations, hardcore street applications

- Cast in 355T6 aerospace aluminum, using Clean Cast Technology™ — smoother airflow

- Multi-angle valve seat cut

- Standard spark plugs; bronze valve guides:

P/N 54501 (CNC-machined) and

54510 (Sprint Car) have a 291cc intake port, 93cc exhaust port, and 69cc combustion chamber; 2.200 intake; 1.615” exhaust [No-valve-job P/N 54500] - 12° valve angle (less piston to valve angle) and .220” raised intake runner (compared to stock LS7) – better line of sight into cylinders

- 6-bolt head design – better clamping

- Improved water jacket

- Compatible with RHS LS race blocks and GM LSX blocks

- .75” thick deck surface – stronger, to withstand higher cylinder pressures

- .40” raised rail – can use with aftermarket rockers

- .100” raised exhaust port allows stock or aftermarket manifolds

Where they went, they did well: “We wanted to design every advantage into the heads, and still make it possible for a guy to just bolt them on, without spending a lot of money at the machine shop; so we looked at the LS7 heads, and raised the ports .220″ to improve line of sight into the cylinder and made it 6-bolt compatible for our block and the GM block.” That 6-bolt head becomes important, when guys add superchargers!

RHS has an existing line of cathedral port heads in both as-cast and CNC-ported, but for all-out power, the rectangular port heads are becoming more common. “The stock L92 rectangular heads work really well out of the box for production parts, so there was no need for us to go there.” Even so, “We didn’t want to require a lot of high-dollar components; our heads will bolt right on an LS7, even using the stock manifold.

We also designed around the LS7 rocker arm, and we make our own rocker stands — or the builder can use the existing parts.” With the tall deck, you could have an intake manifold issue, so RHS offers spacers, for LS1, LS3, and LS7, so the customer can use his existing intake manifold. All you’re going to need is a timing chain, and when we know what you’ve built, we can sell you the right one.”

So, Do I Start at the Top or at the Bottom?

Since mix-and-match, components-built engines require plenty of advance knowledge for even the expert builder, RHS has comprehensive tech notes. Sifting through these clear instructions will help the informed builder get the parts he really wants, right from the start. Everything, from torque values to recommended assembly lubricants, to head gaskets and freeze plugs, is right there in front of the builder.

With this information, it’s easy to plan the engine compartment in advance, rather than waiting until the engine is nearly finished before, say, ordering your AN hose fittings. A large number of helpful FAQs and article links are also provided.

It doesn’t hurt to look through these before you fill out the order form! As Feeney says, “We go out of the way to make it as user friendly as possible and provide all of the components and accessories to go with it to help with the learning curve.”

While the nitty-gritty details are still left to be disclosed, RHS was very forthcoming with some spy shots of their intake and exhaust ports as well as this snap shot of the combustion chamber. While not yet released to the public - at the time of this writing - RHS' LS3 and LS7 heads are sizing up to be real game changers.

Building to a horsepower-point involves a lot of planning. A small engine and a large engine can both make, say, 600 horses. It’s just that the 502 may hit its horsepower peak 2000rpm lower than the 350 will. What you plan to do with the car and how long you want to go between rebuilds are what determine your configuration.

Feeney says that, “If someone is going to do just a basic investment, they should probably look at a head swap, but if their long-term intention is to have a large cubic inch engine then they should start with a solid foundation in the block. Again, on the machining side of things, we offer a finished, honed block ready to assemble. Even the cam bearings are already installed.

“When you’re perusing the parts catalogs on line, remember that companies like RHS spend a lot of time actually testing things, and why they want builders to think of the total engine package, from air cleaner to exhaust tip, in the early design phase.

For both the LS3 and LS7 heads, RHS has a catalog of high performance valvetrain hardware that is certified to take everything that the new heads and blocks are capable of dishing out.

While a gifted amateur may occasionally stumble into a decent “off-book” setup, that’s not the way to bet. It’s smart to put your money where the research is, and build a good system that you know will fit your needs.

[17]Feeney summed up: “We are shocked how many are in weekly driver applications. With our block, it’s really easy to add cubic inches. We can add inches and still be reliable. You can build a lot of horsepower, really economically. It’s phenomenal how many horses regular customers can get, just making engines at home. It’s mind-boggling.”

[17]Feeney summed up: “We are shocked how many are in weekly driver applications. With our block, it’s really easy to add cubic inches. We can add inches and still be reliable. You can build a lot of horsepower, really economically. It’s phenomenal how many horses regular customers can get, just making engines at home. It’s mind-boggling.”

Big Plans On The Horizon

Never one to be caught sleeping, we’re gearing up to build us one helluva LSX monster totaling out at 500 cubic inches. Employing RHS’ new Race Block and LS7 heads, we’ll be going to LME [18] out of Houston, Texas, who will bolt together the lightweight race plant with Wiseco slugs with Total Seal rings, a Lunati [19] crank and connecting rods, ARP hardware, a Moroso pan with a Melling pickup and bunch of other goodies.

LME is a top-flight LS engine builder and we’re excited to be partnering with them on this build. Expect to see this machine putting out some serious numbers on the dyno and sitting between the fenders of LSXTV’s project “All Air.” How’s that for a teaser?