Previously we covered the buildup of the bottom half of this engine built by Powerhouse Engines and Street Machine Magazine at the Powerhouse facility in Warragul, Victoria, Australia; the guys were kind enough to share the details of the entire buildup with us. In the first installment, we discussed the repair of the engine block, which had suffered an impact from a water pump shaft and needed a new sleeve to prepare it for use.

This installment, the second and final of the series, covers the top end and dyno sessions.

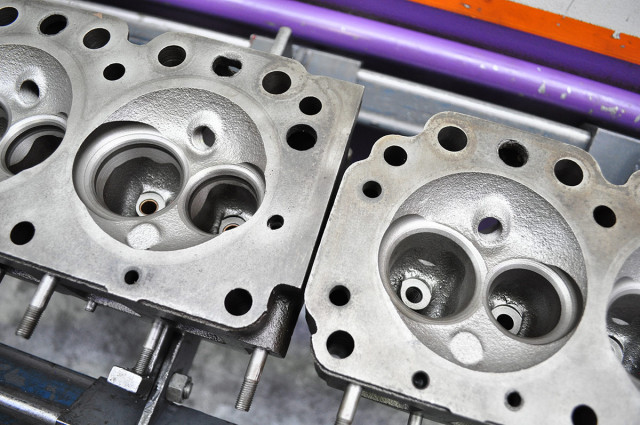

“Chrysler’s Hemi Six head comes in two basic flavours. There’s the 215/245-spec head with a 1.84-inch intake valve and 1.50-inch exhaust valve, then there’s the 265 version with a 1.96-inch intake and 1.60-inch exhaust. We took three heads to Johnny and his team at Powerhouse Engines to see which was best,” says the engine’s owner, Scotty Taylor.

A comparison of the 245 (left) and the 265’s combustion chambers (right). Even with larger 265-style valves the 245 head couldn’t match the 265’s performance on the flow bench. More on this down below.

A stock 245 head, stock 265 head, and modified 245 head with 265-style valves were all inspected to determine which would be best for the application. The 245 head with 265 valves is a low-buck trick; as the 245 head used a smaller combustion chamber, it provides an instant boost in compression with no extra work, and adding the larger valves bumps the cylinder head flow up to the level of the 265 head – at least in theory.

The Powerhouse Engines Superflow SF-1020 flow bench was employed to test all three castings, and that testing immediately showed a number of potential pitfalls to the plan. Using the 245/265 combo head did not perform much differently from the standard 245 head, due to the narrow port throat inside the casting.

Flowing the cylinder heads on the in-house Superflow SF-1020 bench gave the Powerhouse team a solid starting point in terms of information.

The 265 head, on the other hand, flowed an average of 14cfm more across the curve, but it presented its own issues, especially in relation to the combustion chamber dimensions. With a whopping 92cc chamber, it would be impossible to pump the compression above 8.0:1, even with the use of a flat-top piston at zero deck. The 245 cylinder head’s 84cc chamber would help bump the compression up, but not over 9.0:1, and definitely not without extra help.

Cylinder Head Mods

“Johnny wanted the compression up around the 10.5:1 area, so we took the 245 head and shaved about .070-inch off it to drop the combustion chamber size to 67cc; something we couldn’t do with the 265 head,” says Taylor. Final static compression after the decking finished out to be 10.6:1.

Time in the porting room improved the performance of the 245 castings to well above that achieved by as-cast 265 cylinder heads.

Now that the compression ratio was sorted out, the cylinder head underwent other changes designed to improve its performance, including a new set of 2.02-inch intake valves. Exhaust valves remained at the stock 1.60-inch dimension; stainless valves were used throughout.

Cutting the new hardened valve seats for unleaded fuel compatibility. A five-angle design was used on the intake side, with four angles directing exhaust flow out of the ports.

The trick came in opening up the port throats – Powerhouse chucked up the die grinder and added 5cc to the intake port runner volume by cleaning up the port throats and short turn radii in each intake port, flow on the bench picked up 40 cfm to provide exactly the performance improvement needed to make the hybrid 245/265 cylinder head work properly for the application.

In the interest of remaining budget-friendly, cast-iron valve guides were fitted into the castings, while new hardened exhaust seats and beehive valve springs were also installed. Springs and retainers are from Crow Cams.

A five-angle valve job was performed on the intake side, while the exhaust ports received a four-angle grind.

Another modification came as Powerhouse trimmed down the rocker pedestals .320-inch (seen below) to accept a set of ARP screw-in studs while maintaining proper geometry; COMP Cams 1.72:1 roller-tip rocker arms sit on top.

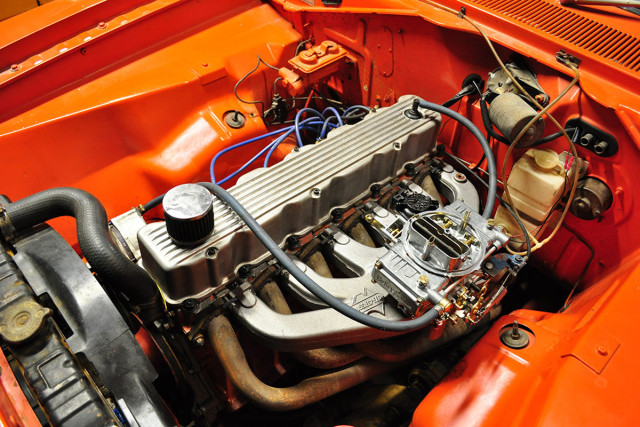

Now that the cylinder head was finished up, the team initially outfitted the engine with a Pacemaker header, a Redline four-barrel intake manifold, an Aussie-market-only 470cfm Holley carburetor, and the testing began.

Dyno Testing

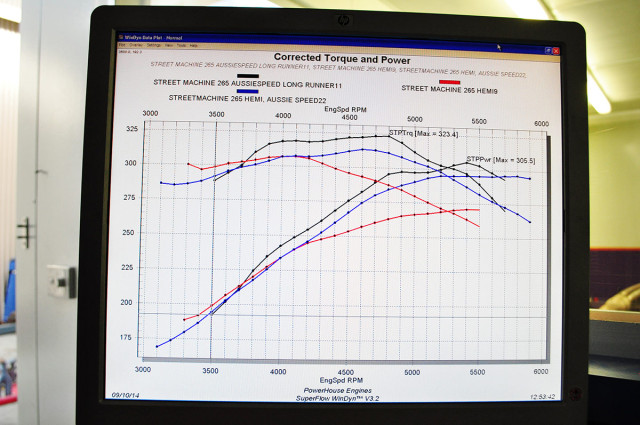

The goal for this engine was to crack the 300 horsepower mark with a bit of creative machining and parts selection.

Doing so would require a fair bit of parts-swapping on the dyno, as the Powerhouse team discovered some issues on the first day that required a second look.

Twelve little soldiers, all in a row. Lined up and awaiting time on the dyno are COMP Cams roller-tip rockers and a full complement of Crow Cams valvetrain gear; sitting inside are stainless valves from Ferrea.

“With the Redline intake the engine made excellent low down torque, especially below 3,500 rpm, but it seemed to lay over at 4,200 rpm. We found it liked a two-inch spacer; the best we saw with the 470 cfm Holley was 271 horsepower at 5,400 rpm and 307 lb.-ft. at 4,100 rpm,” says Powerhouse owner John Pilla.

Problems can crop up in the most unsuspecting places; in this case, the head bolt recesses were leaking water. Powerhouse machined the areas causing the problem, and pressed in custom inserts secured by high grade sealant to solve the problem.

After this first day of testing, it was discovered that the ported cylinder head had some porosity issues and had filled the oil pan with watery oil. The cylinder head was removed and pressure-tested, and a few of the head bolt recesses were found to be leaking water into the engine.

Once the issues were repaired, the decision was made to test out an Aussiespeed AS0265 4bbl intake manfold.

This manifold has longer runners than the Redline manifold, and also includes a divided plenum. As with the Redline manifold. a two-inch spacer was tested along with the 470cfm Holley carburetor.

In this configuration the engine made 286 horsepower at 5,400 rpm – a 15-horse gain over the Redline intake.

A final decision came in the form of a 650 cfm double-pumper Holley carburetor, along with jetting changes dictated by the performance of the engine on the dyno. A variety of spacers were tested, with the best performances coming from the use of a basic two-inch open spacer.

The final round of testing came with a different version of the Aussiespeed intake manifold that was still in development at the time of this testing.

A comparison between the two intake manifolds that were tested on this engine. ‘To get over the 300hp mark we had to try the Aussiespeed long runner intake. It also showed some distribution issues – exactly opposite to the Redline, but you can’t argue with the power. To show the true horsepower potential of this motor we could have tried a set of triple Webers, but they were way outside our budget for this engine,’ says Taylor.

When testing was complete, the dyno showed 305.5 horsepower at 5,400 rpm and 323.4 lb.-ft. torque at 4,800 rpm. Even better, over 300 lb.-ft. of torque are available through a wide powerband – 3,700 to 5,300 rpm.

Not bad for a bunch of parts that were destined for the scrap heap – and perfect sleeper motivation for Taylor’s Valiant wagon.

Thanks to Powerhouse Engines and Street Machine Magazine for sharing the details of this buildup with us – keep working on the cool stuff, guys!

A burnout from the bullet –