A lot of people are always asking themselves what the meaning of life is. To us, life is all about evolving. Evolution is everywhere you look. It happens every day in fashion, movies, and music. Well maybe except for music. But even the way we listen to music today compared to how we did 10 years ago has evolved; look no further than MP3’s and iPods. When we growing growing up, you were cool if you had a portable CD player, especially one that didn’t skip constantly.

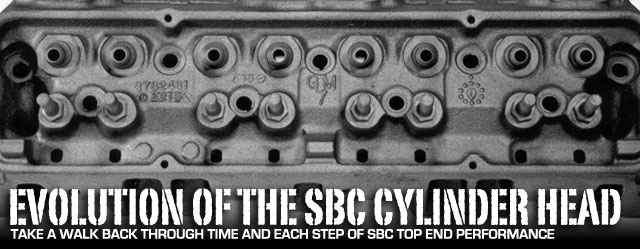

[2]

[2]The engine that started the legacy, the 265, was Chevrolet's first foray into affordable V8 performance in an entry-level sedan, not that of a big full-sized performer.

So evidently, evolution is a good thing, and the small block Chevy engines that have been pumped out of the General’s engine plants all over the world are no exception.

With the small block making its debut for the 1955 model year, no engineer back then could have imagined where we would be today with 638hp, 376 cubic inchers that are still able to pull 26mpg on the highway and produce low 11-second quarter-mile time slips off of the showroom floor!

But like everything else; there were setbacks, growing pains, and something called the Smog Era, which was basically like the dark ages for automotive technology. As usual, GM weathered the storm and got us through it, and what resulted is the modern LS family of today.

Today, the small block Chevrolet is one of the most iconic mainstays of the hot rodding industry. From boats, small aircraft, to lakesters and European knock-offs, the SBC is a legend not due to its numbers but its longevity.

265

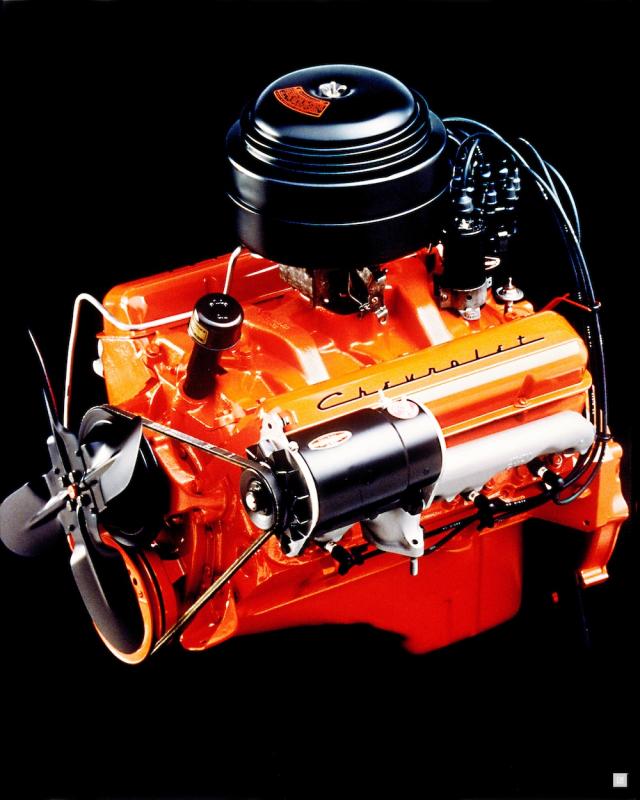

In a thread that would follow the small block throughout its existence, the original 265 can trace its existence back to the never-content engineers and speed freaks in the Corvette division. Looking for a suitable replacement of the “stove bolt” inline-six, Ed Cole and Zora Arkus-Duntov birthed the plant in a furious 15 weeks.

The 265 small block was released in the all-new for ’55 Chevrolet models ranging between either a 162 or 180hp carburetion and camshaft package. A huge step in placing Chevrolet in the public eye as an “everyman performer,” this engine carried over for ’56. It was an available option for all Chevrolet passenger cars, pickups, and was instrumental in raising the prestige of the Corvette.

283

With a release in the final year of the “Tri-Five” – the 1957 Chevrolet – and being the first Chevrolet engine offering factory fuel injection at the lauded 1hp-per-cubic inch output, the 283 was one impressive engine for its time and it’s considered a milestone in Chevrolet history. Originally, the 283 was merely an overbored 265, but engineers found that the previously-cast block’s walls were thin. A thicker-cast block needed to be produced.

Five variations of the 283 were made available in 1957 alone, ranging from 185hp to 283hp thanks to the option of a single, dual carburetor or “Fuelie”induction system. The Rochester-built mechanical fuel injection rose as the crème de le crème of the 283 packages. The fuel injected version of the 283 was also an available option on the passenger car line as well as the Corvette, making anything powered by this rare and unique plant a collector’s item today.

327

Introduced in ’62 and available on all models from the compact Chevy II to the sporty Corvette, the high-revving 327 came in a variety of specifications throughout its short-lived lifespan ranging in horsepower numbers of 210 to 375, respectively.

The highlights being the 365hp L-76, and the 375hp L-84 which the latter included mechanical fuel injection, and was the highest horsepower-per-cubic-inch engine (1.146hp-per-cube) ever offered by the manufacturer until the Gen III LS6 of 2001 came along. The 327 essentially used the 283 cast iron heads, but with larger valves.

Only being available for three model years, and offered exclusively as the standard engine in the Z/28 Camaro of ’67-’69, this “little engine that could” combined components from the 283 and the 327, respectively, having been designed primarily for the Camaro’s entry into the Trans-Am racing series.

The reason for such a small displacement was the rules set by the T/A series and the SCCA (Sports Car Club of America) that no vehicle was to displace any engine larger than 305 cubic inches. The end result of this combination of parts would result in a factory-proclaimed, but underrated 290hp, although some say the real output was closer to 350hp.

These engines would go on to be synonymous with the first generation Z/28, and though it wasn’t much of a 1/4-mile star with times in the low-15s, that high-revving 302 would scream around any road course you put it on.

We talked to Ron Sperry, GM’s Powertrain Component Design Engineer who was hired on at GM in 1969, about the famous 302, “These were developed before my time, and most of the guys who had engineered them had their work cut out, since it was an all-new idea at the time. Depending on application, the only real difference between any of these castings were the valvetrain pieces, and the casting numbers, but they were excellent units for their time given the technology they had to work with in those days.”

350 (L-46, L-48, L-82, LT-1)

The 350 was the longest-lived small-block Chevrolet engine made, and it has powered everything imaginable. In it’s initial form, it was introduced as the 300hp L-48 in the ’67 Camaro, and eventually found its way into all of the other Chevy models as time went on. The high point of this powerhouse was the 360hp variant that was the LT-1 version. As performance (or what was left of it) limped along during its absolute low-point during the mid-‘70s to the early ‘80s, the Corvette made due with an underpowered, though somewhat respectable for the era, L-82, producing in the neighborhood of 200hp, depending on year.

Although the engine was finally put to rest in most applications around the turn of the century, they were still being produced in Mexico until 2004, as a result, over 90,000,000 Gen 1 small block Chevys were made. The latest and highest performing (in net numbers) version dubbed the L98, which we’ve decided to give it’s own section as it was the only MPFI Gen-1 350 that was made.

Ron explained, “I was hired on at GM in 1969. By that time, the L-48 was already up at running under the hoods of many Chevy muscle cars. What many people don’t realize is that these heads would change very little until the mid-’70s, when fuel economy and emissions took over as the key factor over performance, we would later go on to develop the ‘swirl port design’ that would live on in models until the late ’80s.”

- 350 (L98)

Proving that Chevrolet was making an effort in injecting its models with much needed performance during the ‘80s was the aluminum head version of the L98.

The aluminum L98 castings were the result of our racing efforts, and it showed as it gave the Corvette and F-cars the much needed performance they rightfully deserved

While often over-looked by builders today, the factory castings of these heads have been reincarnated as the GMPP ZZ4 head, and they are still available over the counter at any GMPP retailer.

“These were the first purpose-built, factory-produced high performance heads in a long time,” Ron clarified. “The aluminum L98 castings were the result of our racing efforts, and it showed as it gave the Corvette and F-cars the much needed performance they rightfully deserved.”

400

As a way of attempting to maintain horsepower levels while slashing compression ratios, the 400-cubic-inch small blocks arrived just in time to see the pinnacle of classic high-performance in ’70 with 265 gross horsepower, before having its plug pulled after the ’76 model year with it producing 175 net horsepower. It was found in everything from intermediate-sized coupes, to full-sized pickups.

Although it never was truly a performance engine (with smog-era 350’s of the same vintage producing more power), it would later become a favorite among circle-track and drag racers for a time, most likely due to their plentiful and bargain-priced availability.

Even so, these heads – also known as the 882 castings – had a double heat-riser passage and were prone to cracking because they ran so hot. With the current aftermarket now producing better offerings, personally, we would leave these on the shelf when it comes time for your next engine build.

LT5

In an effort to dig a little deeper into the history of these classic heads, we enlisted Ron’s help. Sperry was involved with developing a number of the different SBC engine pieces found in a large variety of GM’s performance offerings, most notably, the aluminum TPI, LT5, LT1/4, and the original LS1 heads.

Kicking off the ‘90s with a bang was the aluminum head LT5 that was exclusively found in the original ’90-’95 ZR-1 Corvette. It was produced in partnership with Lotus and Mercury Marine, and was purely designed with performance in mind. No other variants were made of this engine, and it’s the lone DOHC unit on our list.

Although the LT5 maintained a DOHC, 4-valves-per-cylinder design throughout its life span, changes were made during the run, and as a result, horsepower levels changed, as did the casting numbers. Spark plugs were located in the center of the combustion chamber for maximum power.

There were there different versions of the LT5 cylinder head, although they are all very similar. This cylinder head is unique to the LT5 Corvette engine, and is not compatible with any other engine platform.

LT1/LT4

Following hot on the tail of the LT5, and designed as a replacement for the L98 head, came the short-lived LT1. Not to be confused with the LT-1 of 1970, the Generation II small block’s head came in either aluminum or iron, and packed anywhere from 260hp-315hp (depending on application).

While the aluminum versions were found exclusively under the hoods of F-bodies and Corvettes, it was in the full-sized B-body car line (Caprice, Impala SS, Fleetwood, Roadmaster) where the iron head version resided.

But before the LT1 was killed off, a limited run of LT4 engines were created to send the Generation II small block out with a bang with a total of 330hp. While the castings were similar and the bolt patterns identical to the standard LT1 (making it very possible and very popular for a head swap for tuners), it was in the port design that made all of the difference.

“These were the first real redesign of the SBC head as we knew it,” Ron remembered. “Where the L98 Corvette was making at best, 250hp, these heads in combination of the changes we made with the LT1 engine itself were good for another 50hp, up to a total of 300 for the ’92 Corvette. After this point, the Corvette design team had to refocus their efforts on the chassis of the car, as the increased horsepower and torque changed the driving dynamics of the earlier C4 design.”

It All Comes to A Head

The LS series of engines picked up where the LT1 and LT4 left off with the introduction of the C5 Corvette. It would later go on to revolutionize the SBC as we know it, earning the moniker of “Generation III,” although many LS loyalists within the hobby struggle to acknowledge them as small block Chevy plants.

Having said that, unless you’re into date-code numbers correct, concours originality, we see no point in scrounging for rusty, used relics from a swap meet for your high performance needs, when the aftermarket currently offers limitless amounts of options for your small block Chevy. With where we are in terms of technology and design, you would only be going backwards anyway, and where’s the fun in that?

We would like to personally thank Ron Sperry for his time and courtesy to take a few minutes to talk to us about the evolution of the Gen 1 and Gen 2 heads, and we look forward to working with him again in the future for other feature articles.