There has been a boom in corn and sugarcane-based ethanol fuel production and consumption since the early 2000s. And performance enthusiasts have become divided on the use of this biofuel in the realm of motorsports. Some claim that it will cause vapor lock, damage your engine and destroy your fuel system; while others say that it’s nothing more than a “green energy scam.”

What about the more open-minded of our community, and the engineers behind racing series like IndyCar, NASCAR and American Le Mans? Where these series have found the benefits of ethanol-based fuels in performance applications to outweigh the drawbacks.

We sat down with some of the industry’s best from AEM Performance Electronics, Fuel Injector Clinic and VP Racing to set the facts straight on E85 and ethanol-based fuels use in import and domestic performance vehicles.

The History Of Ethanol And The Automobile

Ethanol is nothing new, it has been consumed by humans in the form of liquor for thousands of years and has been used as a fuel source for cooking, heating and light since the infancy of modern chemistry. Probably even fewer people realize that ethanol has also been used as fuel for internal combustion engines since the introduction of the Otto Cycle engine itself.

Shortly after the Civil War tax on industrial alcohol producers was repealed in 1906, Henry Ford introduced the Model T as the first mass-production vehicle designed to be ran on pure ethanol and ethanol/petroleum mixes. Ford believed that ethanol and other biofuels would become “the fuel of the future” and that America would eventually grow its own fuel. That is until the prohibition era of the 1920s began and the falling cost of oil production stole the spotlight, thanks in-part to government subsidies and the Texas oil boom happening at the time.

Decades later, ethanol began its slow but steady comeback in the early 2000s, when it was used as a replacement octane booster in pump gas after MTBE was found to cause groundwater contamination. So now the ethanol content in standard gasoline at the pump in the United States stands at E10 (10 percent ethanol and 90 percent gasoline), and many states are beginning to adopt E15 blends.

This affordable and often underappreciated energy source has a growing following among the cult of power hungry enthusiasts and professional racers — spanning many different motorsports disciplines — that have found the 20 percent or more increase in power to be worth the roughly 30 percent drop in fuel economy (using current technology anyway). And the benefits are especially worthwhile for forced induction applications.

Thermodynamic And Chemical Properties

Freddie Turza of VP Racing Fuels was kind enough to give us a short lesson on the thermodynamic and chemical properties of ethanol versus that of standard pump gas, and other race fuels.

“There are a few major concerns specific to ethanol-based fuels that we should get out of the way first,” says Turza. “The first issue being that E85 just doesn’t have an equivalent BTU value to that of a conventional fuel. Which means that ethanol has less potential energy than pump gas and generally requires roughly a 30 percent greater volume of fuel to produce the equivalent energy to that of standard gasoline.”

“Another concern is that, depending on the climate you live in, the true ethanol content of the ‘E85’ found at your local gas pump may be inconsistent throughout the year,” explains Turza. “This is why aftermarket retailers sell those ethanol content testers, because you can never be totally confident in what you’re actually getting,” continues Turza. “If your engine is tuned aggressively on a true E85 blend, and fill up in the winter [when the ethanol content is much lower in some climates to aide in cold start] your engine will likely run poorly and possibly even cause engine damage.”

“At VP Racing we set out to develop a capable ethanol-based fuel for our customers that is pure and always maintains a consistent ethanol content from drum to drum, giving peace of mind and much more consistent power output.”

VP Racing's three ethanol fuel blends.

“Ultimately, VP has developed three different formulations, and it’s important to point out that the hydrocarbon [standard gasoline base] that we use in these fuels is derived from only high quality base stocks,” explains Turza.

“First, we offer our entry-level X85, which contains a standard 85 percent ethanol and 15 percent hydrocarbon blend that competes closest with the price of standard E85 from the pump,” continues Turza. “For racers seeking a higher ethanol content or need to blend another specific content on their own but want the same reliability as our X85, we have X98. And for professionals and enthusiasts demanding the ultimate in performance we created C85, which is essentially X85 on steroids, due to the addition of proprietary components that further increase power.”

Similar to VP’s line of Q-racing fuels, the additional benefits of the C85’s formulation over a standard ethanol-blend are only going to be truly realized through proper fine tuning of the engine calibration.

Flex Fuel Hardware And Engine Management

AEM’s Flex Fuel Wideband Failsafe monitors and displays ethanol content, boost/vacuum and air/fuel ratio; and can even trigger an output for a failsafe strategy if your engine runs too lean.

As we discussed earlier with VP Racing — it has been understood that, depending on the climate you live in, the ethanol content of the “E85” at your local pump may have an ethanol content drop of as much as 15 percent in the colder months.

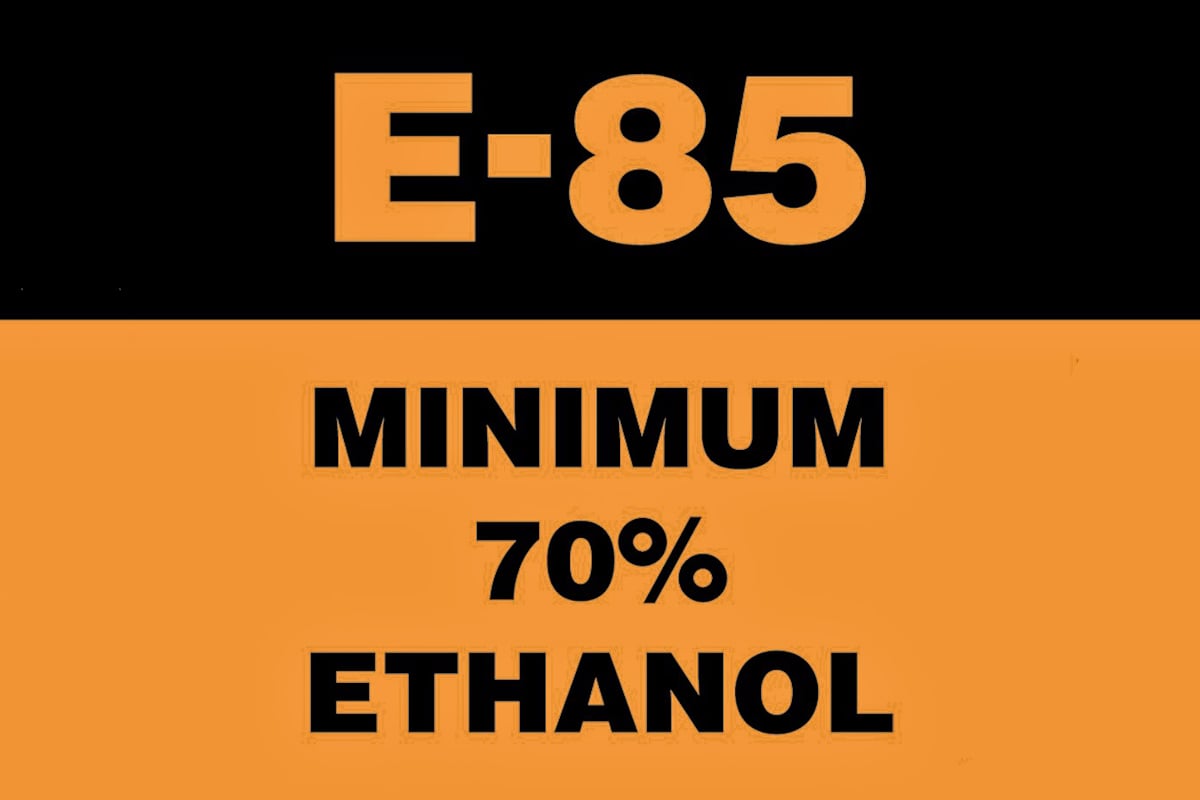

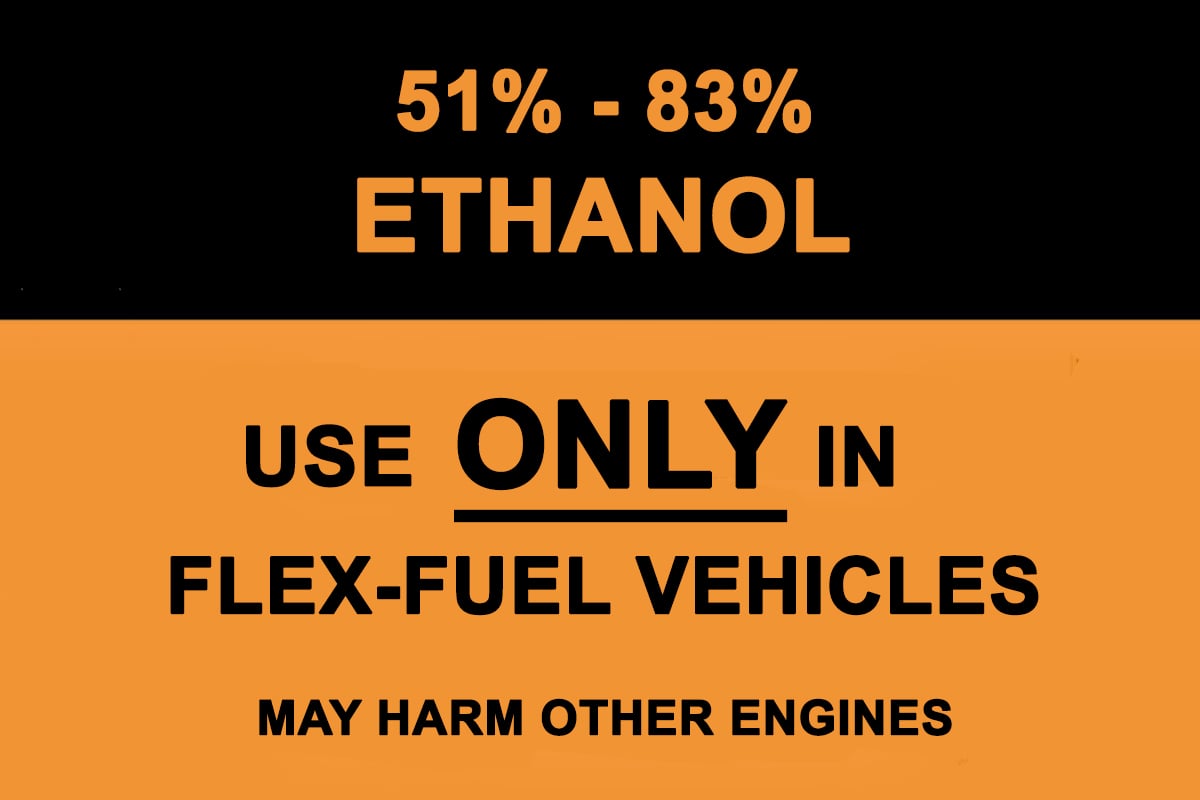

But this has become an even more important issue for enthusiasts converting to ethanol blends since the U.S. Federal Trade Commission officially adopted the ASTM D5798 standard in July of 2016. This allows for an ethanol content swing of as low as 51 percent, presenting a number of potential issues for ignition timing and fueling targets when your engine has a conservative E75 calibration, but are instead unknowingly running on E51.

The previous tag used to identify "E85" pumps conforming to U.S. Federal Trade Standards prior to July of 2016 (left), and the new tag identifying pumps meeting the new ASTM standard adopted by the U.S. Federal Trade Commission in July of 2016.

Luckily, AEM Performance Electronics has a few aftermarket and OEM-influenced solutions to keep your engine happy and relieve your tuner’s anxiety. And we had the opportunity to talk to AEM’s own Devin Pearce to go over the hardware and electronics side of converting to ethanol.

“Before any enthusiast takes the final leap over to E85, it’s critical that they first make sure that their fuel system is up to the task of handling the additional fuel volume requirements and the corrosive nature of ethanol,” states Pearce. “Sure many are aware that you need to look at things like fuel pump flow and injector sizing, but an area that is often overlooked is the physical chemical compatibility of each fuel system component. Ethanol is corrosive by nature, so it’s important to verify that components such as fuel lines, injectors, fuel pump internals, plastics and certain metals are up to the task.”

You may have heard the term “Flex Fuel” being used by automobile manufacturers and you’ve probably seen the badges on newer GM, Ford and Chrysler vehicles in the last few years. This is simply a marketing term used to describe a late-model vehicle that is capable of switching between both regular pump gas and E85 without any input from the driver, other than filling up the tank.

In theory, the maximum lean air-fuel ratio power potential of both pump gas and E85 are very close, but the reality is that you will never be able to achieve that max lean power potential with gasoline because of its greater sensitivity to knock, -Devin Pearce, AEM Performance Electronics

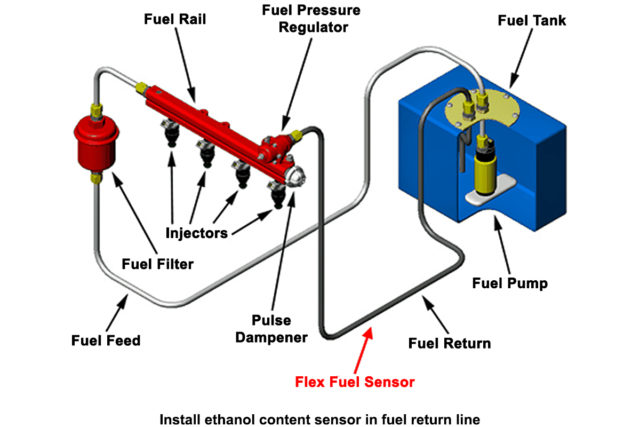

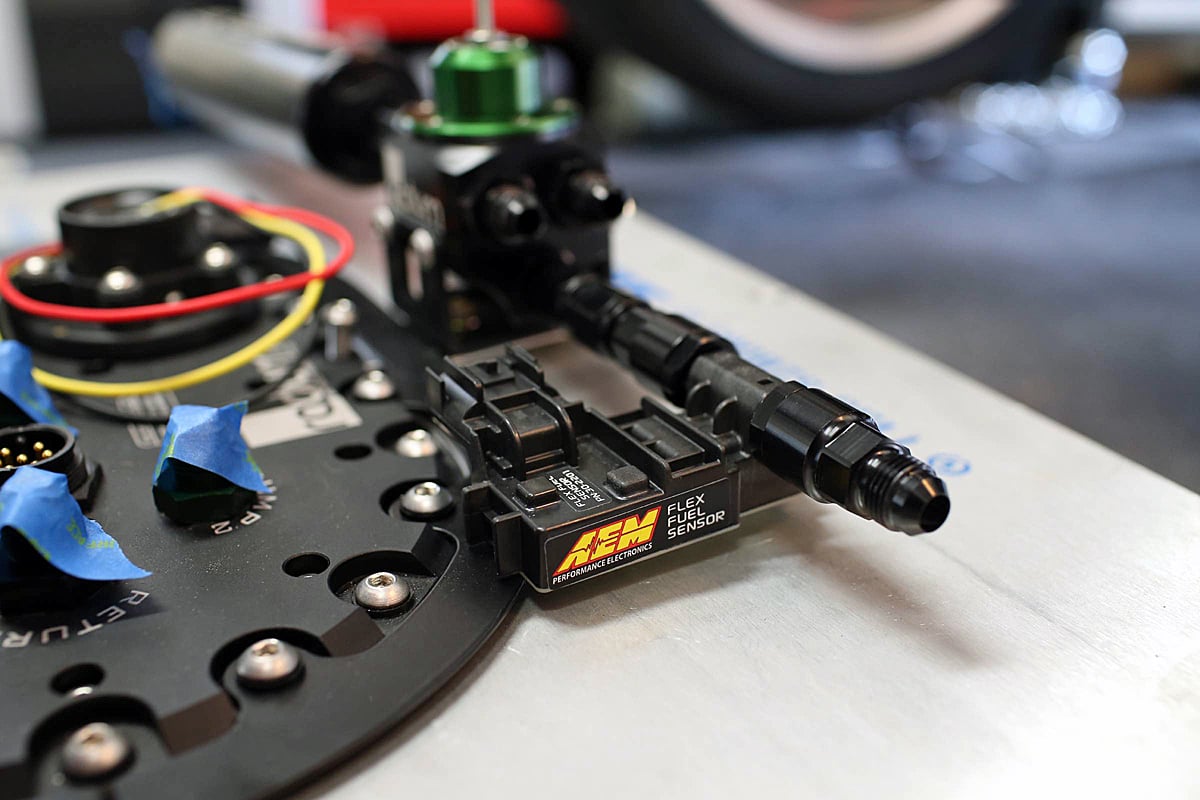

Now, your average joe vehicle owner probably doesn’t comprehend or even care about the drastic change being made behind the scenes, but for the more mechanically inclined and tech junkies, this ability to change fuel types on-the-fly is achieved through the use of a flex fuel sensor and advanced engine management features. For aftermarket solutions, companies like AEM offer OEM-style flex fuel sensors that can be integrated into standalone management systems, some high-end factory ECUs, and external reference gauges.

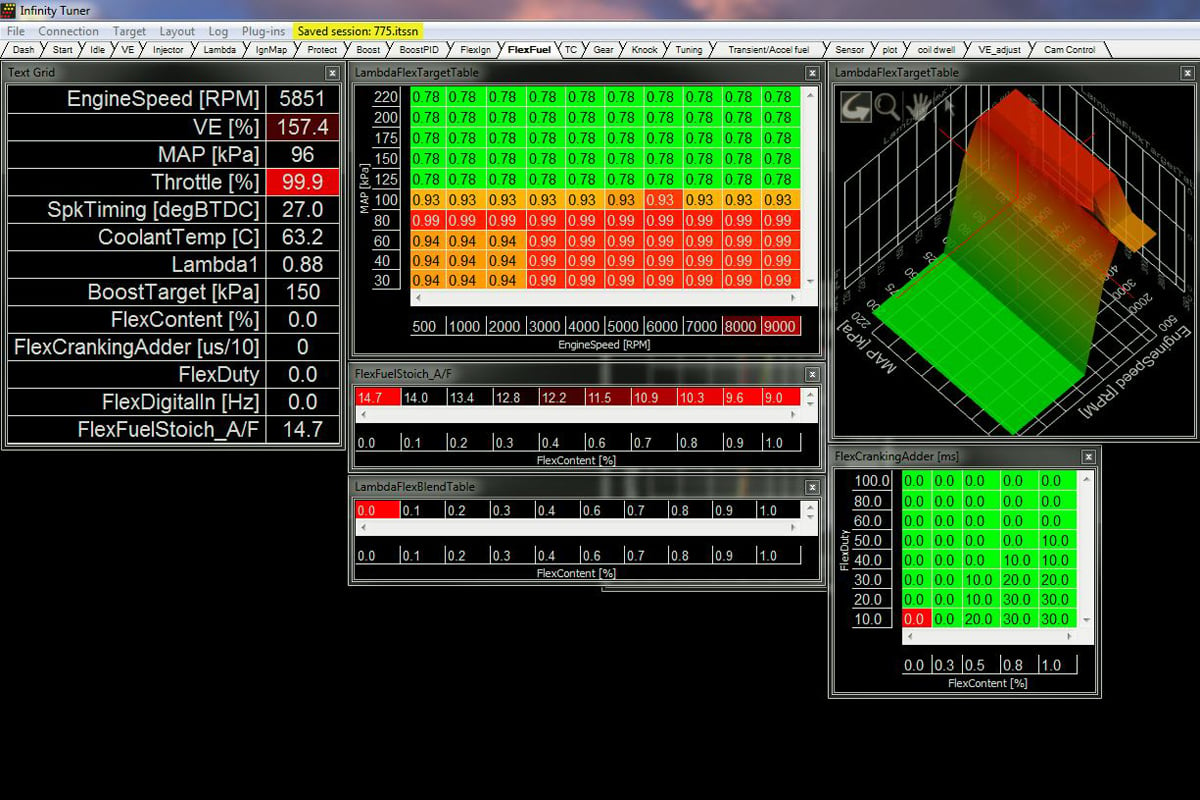

“The flex fuel sensor is installed within the fuel return line, and is utilized by enthusiasts in a number of different ways,” says Pearce. “It can be used simply to monitor the true ethanol content of the fuel via a user readable external gauge, or it can interface with an aftermarket ECU, such as our Infinity series, which is just a basic wiring task. From there your tuner can set up the calibration to actively monitor the ethanol content and automatically interpolate between multiple ignition timing and fueling maps — ranging from pure gasoline all the way up to straight ethanol.”

With this system properly installed it essentially eliminates the concern of engine damage or the poor running conditions commonly experienced due to a lower ethanol content than expected. It also cuts out the need for the driver to make manual map changes using a switch or button to alternate between fuel types and ethanol content.

AEM's flex fuel sensor (left) and the AEM Infinity tuning software with example flex fuel ethanol blend maps (right).

“In theory, the maximum lean air-fuel ratio power potential of both pump gas and E85 are very close, but the reality is that you will never be able to achieve that max lean power potential with gasoline because of its greater sensitivity to knock,” states Pearce. “It’s a similar story with ignition timing. You’re going to have a hard time achieving whatever the ideal ignition advance is for best power on pump gas due to its higher propensity to knock. Whereas ethanol — just like race gas — allows you to take advantage of more aggressive ignition timing advance to make more power due to its lower burn temperature and higher comparative octane rating.”

“Let me layout a scenario for you, and we’ll use an arbitrary ignition timing value of 25 degrees advanced [BTDC] at peak RPM,” proposes Pearce. “If you ran the engine on a dyno using pump gas first and then switched over to E85 for the next run and left the ignition timing at 25 degrees, you might not see any significant performance gains. Ethanol, like race gas, has the ability to run more aggressive cylinder pressure than pump gas due to its greater knock resistance.”

“Another topic that comes up a lot when we’re out doing field training or seminars is exhaust gas temperature (EGT). When the topic of conversions from pump gas to ethanol comes up during EGT discussions, we always tell them to be careful,” says Pearce. “Right off the bat you could see significantly different EGTs [hundreds of degrees F in some cases], but it’s not an apples to apples comparison with pump gas. That change in temperature can be influenced by a number of factors from the fuel type and air/fuel ratio, to timing advance.”

When it comes to fuel injector data and what it takes to run your injectors on E85, we couldn’t think of anyone better to turn to for insight than Tim Jilg, General Manager of Fuel Injector Clinic.

It is in part the water content in the E85 that makes it the ‘poor man’s race gas,

-Tim Jilg, Fuel Injector Clinic

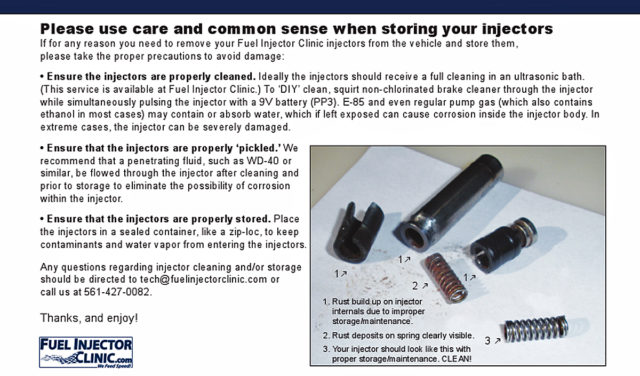

“However, when you start looking at some of the largest injectors on the market, you will learn that the industry standard is to use injectors with improved short pulse control through the use of a ferrous metal valve inside,” explains Jilg. “For these injectors, it makes sense to run pump gas through the system on occasion, use fuel additives to prevent corrosion, or maintain a diligent service schedule that includes pickling the injectors [see infographic below] when not in use or when exposed to air.”

As stated by both Turza and Pearce, molecule for molecule ethanol has less potential energy than pump gas, which means that your engine needs around a 30 percent larger volume of fuel. This greater fuel volume requirement generally requires a higher flowing set of fuel injectors.

“Since it requires roughly 30 percent more E85 by volume to make the same horsepower as gasoline, that means your engine now needs 30 percent larger injectors to make the same power,” says Jilg. “Converting a high horsepower application to E85 generally makes injector scaling much easier at low pulse widths, though. The larger fuel volume requirements help to extend the injector’s operating time and put them into a much more linear operating range down low [higher minimum IPW], helping your vehicle to run much smoother at idle and during part throttle cruising.”

“It may also be of interest to the scientists amongst your readers that it is in part the water content in the E85 that makes it the ‘poor man’s race gas,'” states Jilg. “Since what drives the engine’s intake temperature down, and allows for the extra timing advance that is associated with making more power, is the high latent heat of vaporization needed to evaporate the water [2257 kJ/kg)] component in the fuel, as well as the higher latent heat of vaporization of ethanol [around 900 kJ/kg], compared to that of gasoline [roughly 350 kJ/kg].”

The Future Of Ethanol And What It All Means

For your average performance enthusiast utilizing modern fuel system technology and the latest engine management system, if the system is properly setup for compatibility with ethanol-based fuels why should enthusiasts and weekend racers pay upwards of $12 per gallon for race fuel when they have a proven alternative option readily available at a similar price to what they’re used to paying for pump gas? Especially for those among the forced induction crowd.

Whether for political reasons, personal ideologies, or just scientific and historical ignorance, this “new phenomenon” of using ethanol-based biofuels is certainly controversial among motorsports enthusiasts. While some refuse to ever touch E85, the performance improvements experienced by the more open-minded or budget concious of our community cannot be denied.

Not to mention those of IndyCar, where switching from Methanol to E98 (98 percent ethanol and two percent gasoline) netted a healthy increase in power, fuel efficiency and reliability. With power plants engineered specifically for use on ethanol, teams were able to downsize the Methanol fuel cell from 30 gallons in 2005, to 22 gallons in 2007, and eventually 18.5 gallons for the 2012 season through today.

In 2006 IndyCar transitioned from methanol to E90 with a 10 percent methanol blend, before converting to E98 in 2007.

Sure, maybe E85 isn’t the best option for your average commuter car due to the higher required fuel volume today. But this is only because ethanol is an afterthought for current engines that are optimized for efficiency on gasoline. In the laboratory, however, it has been shown that only 20 percent of the heat that is transferred into energy from gasoline is used to actually power the engine. Scientists at the EPA found that engines designed specifically for use on ethanol produce thermal efficiency beyond 40 percent.

With the ever increasing use of cellulosic ethanol or dry milling for corn allowing second generation ethanol production to reach a positive net energy balance, combined with rapid advancements in engine design, we’ll just have to wait and see what technology has in store for the future of this biofuel. Will it change enough minds?